Legislative norms

In Art. 36 of the Housing Code (LC) lists objects related to the common property of the owners of premises in an apartment building (MCD). This list also includes elevators. According to Art. 39 LCD, the burden of spending on maintenance, restoration work in the event of an accident or breakdown falls on them. It doesn’t matter what floor the apartment is on.

How to organize the trouble-free use, maintenance and repair of elevators is recorded in the rules (hereinafter referred to as the Rules) approved in 2017 by Government Decree No. 743. In addition, the technical regulation of the Customs Union 011/2011 on the safety of elevators (hereinafter referred to as the Regulations) and the Government Decree are in force RF dated 10/02/2009 No. 782 (as amended on 03/03/2011). The documents contain requirements for the condition of stationary lifting machines, the procedure for their inspection and other provisions.

Life time

For any equipment, a period is established during which it must be operated without failure. This parameter is usually recorded in its technical data sheet. As for the service life of an elevator in a residential building, the standard is reflected in clause 5 of Art. 4 Regulations. It says here that in the absence of such information in the passport, the period of operation is 25 years. After this period, the elevator cannot be used for its intended purpose without an examination of its technical condition.

The equipment must be inspected by a company accredited for this type of activity; as a result, it determines the maximum service life of passenger elevators. Based on the results of the examination, a report is drawn up, which recommends either extending the operation of the lift, or modernizing or replacing it. Information about the inspection is recorded in the passport of the stationary lifting machine.

Modernization of elevators - features of the procedure

The process of modernizing elevators carried out by our company involves replacing worn-out elevator elements with new parts in order to increase the level of safety in using this lift. We also carry out work that helps reduce energy during operation of the mechanism and reduce the risk of its breakdown.

A huge advantage of repairing passenger elevators using this repair method is that you can prevent breakdowns, and accordingly the lifting mechanism will function smoothly. In addition, modernization can significantly improve the design of the structure and increase the level of comfort in operation.

Elevator Maintenance

In Art. 36 of the Housing Code clearly defines what MOP is in an apartment building. These are basements, roofs, the area around the building, staircases, communications. The same list also includes elevator equipment, the maintenance of which is a mandatory procedure.

The management company (hereinafter referred to as the Management Company) is obliged to carry out maintenance and inspection according to the schedule. Employees of the organization must respond to calls from people who find themselves in a locked cabin and start a lift that has stopped as a result of a breakdown. Repair of elevator equipment is also the responsibility of the management company. It should involve only accredited organizations that are obliged to carry out diagnostics and eliminate breakdowns of intra-house transport.

What does current repair include?

Maintenance involves periodic inspection of the structure. In addition, by contacting our elevator service department, you can count on checking all lifting mechanisms for faults. Depending on the specifics of the concluded agreement between the customer and our company, the elevator inspection procedure can be carried out once a month, quarterly, every six months, or at other agreed times.

The services we provide for routine repairs also include many other works, including emergency evacuation plans, when there is a need to urgently extract passengers “stuck” in the elevator car.

Replacing an elevator in an apartment building

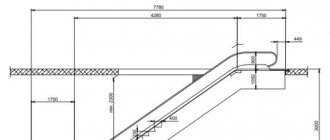

Based on the results of the inspection of the mechanism, a decision can be made to restore individual elements. If this is considered irrational, the lift is dismantled and a new one is installed. The procedure is quite lengthy. It includes the following steps:

- Preparation and examination of the project.

- Construction works.

- Dismantling the old and installing a new elevator.

- Actions on electrification, automation.

- Commissioning works.

- Commissioning of the elevator.

Instead of replacement, it is possible to upgrade the equipment.

Who is responsible

An employee of the management organization is required to undergo special training and certification, know the Rules, and operating instructions. In each company, the person responsible for elevator facilities is appointed by order. Most often, all issues related to ensuring the safety of the lift are regulated by the chief power engineer of the management company.

Replacement of elevators under the overhaul program

The regional capital repair program is considered a real tool to resolve the issue of replacing elevator equipment that has reached the end of its useful life. The decision on the need to install a new device is made by the owner of the multi-storey building, as well as by the general meeting of residents. The preparation of a package of documents is organized, including the technical passport of the house, the conclusion of the authorized company on the development of the operational resource, a technical condition report, as well as a list of works (estimates) to restore the mechanism.

The decision of the entity managing the housing stock and a set of documents are submitted to the territorial body of Rostechnadzor, confirming the feasibility of replacing equipment in accordance with the provisions of the overhaul program. 80% of the funds are allocated from the state fund, and the rest is paid by the owner. To enroll in the program, the following factors are analyzed:

- service life and features of the lifting mechanism;

- the cost of the planned operations and the amount of the owner's contribution;

- general technical condition of elevator equipment and residential building.

Replacement under the program is carried out by companies that specialize in elevator devices. An act of transfer of the machine room to the management organization for commissioning is drawn up. In order to control the timing and completeness of the work, a technical supervision engineer from the Foundation is assigned to the facility.

Residents can find out whether their home's lifting equipment is included in the capital repair program by submitting an application to a representative of the territorial administration specializing in housing issues. To speed up the process, you can go to the administration’s website and look in the section for a list of houses included in the overhaul plan.

Is a major overhaul included?

In addition to replacing new equipment as part of a regional program, other options for financing activities are possible. Owners of residential premises in a high-rise building make monthly contributions for major repairs. This amount is accumulated in a special account and is subsequently spent on major work to restore common property.

Major repairs of an elevator in an apartment building are carried out on the basis of an inspection report. It must also record the fact that the lift cannot be used. Only in this case, replacement of the elevator is possible at the expense of contributions for major repairs. Moreover, the monthly amounts contributed by those who live on the lower floors of the apartment building are also taken into account.

As part of ongoing repairs

This type of work is aimed at maintaining a stationary lifting machine in working condition. If the elevator inspection report lists breakdowns and indicates incorrect operation of components, it is possible to replace individual elements of the mechanism. Current restoration measures imply the prompt restoration of transport if it suddenly breaks down.

WE ORGANIZE A SYSTEM FOR RESOURCE RESTORATION OF ELEVATORS

The elevator resource restoration system includes:

- major repairs (replacement of equipment);

- equipment modernization.

The decision of the Council of the Eurasian Economic Commission dated December 19, 2019 No. 112 “On amendments to the technical regulations of the Customs Union “Safety of elevators” (TR CU 011/2011)” extended the period for bringing elevators into compliance with the requirements of TR CU 011/2011:

- put into operation before the entry into force of TR CU 011/2011;

- the assigned service life for which expired before the date of entry into force of TR CU 011/2011, i.e. before 02/15/2013.

The deadline for bringing such elevators into compliance with the requirements of TR CU 011/2011 is no later than 02/15/2025.

Major renovation

Major repairs ensure the restoration of serviceability, full or close to full service life of the elevator.

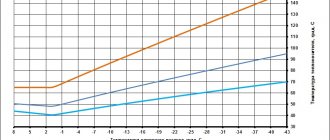

The duration of cycles (in years) between planned overhauls is established as a weighted average (by years of production of elevators in operation) (clause 3.6.1 of the Regulations on PPR) (see Table 2).

During planned major repairs, a specialized organization carries out work to replace and adjust components and parts that have exhausted their service life or are close to its exhaustion. In this case, the following are additionally fulfilled (clause 3.6.2 of the Regulations on PPR):

- work included in routine repairs;

- commissioning works.

In order to reduce the downtime of elevators, major repairs of components and parts by a specialized organization must be carried out regardless of the repair cycle, as necessary (clause 3.6.3 of the Regulations on PPR). This is due to the fact that a large number of components and parts included in the set of elevator equipment have a working life below that regulated for the elevator as a whole.

The durability of the elevator parts and components depends (clause 3.6.3 of the Regulations on PPR):

- on the intensity and operating conditions of the elevator;

- safety requirements;

- factory quality.

The scope of work performed during the overhaul of components and equipment (work of a capital nature) includes the replacement of one or more of the following components (clause 3.6.3 of the Regulations on PPR):

- main drive electric motor;

- winch gearbox or worm gear pair;

- braking device;

- electrical panel (panel) for elevator control;

- compartment cabin;

- speed limiter;

- shaft and cabin door leaves;

- spring and balancer suspensions of the counterweight and cabin;

- traction pulley;

- ropes.

Major repairs of an elevator that has premature physical and moral wear and tear of the equipment are carried out based on its technical condition (clause 3.6.4 of the Regulations on PPR).

Modernization

The decision to modernize the elevator is made by its owner[11] based on the requirements of technical standards developed for TR CU 011/2011 and approved by the Decision of the EEC Board of May 29, 2018 No. 93.

In accordance with clause 4.3 of GOST R 58495-2019, the owner of the elevator must modernize it before the expiration of the service life specified in the elevator passport. The process looks like this step by step:

If the modernization of the elevator is carried out by a specialized organization, then it:

- develops a modernization project;

- carries out organizational and technical measures to suspend the use of the elevator for its intended purpose for the period of modernization;

- supplies the elevator equipment required for modernization;

- dismantles replacement elevator equipment;

- carries out installation of installed elevator equipment;

- draws up, including supplementing, accompanying documentation for the modernized elevator[12].

After upgrading the elevator, the person responsible for operating the elevator in an organization or enterprise will need to receive updated documentation from a specialized organization and store in the archive (clauses 6.4, 6.5, 6.6 GOST R 58495-2019):

- operating manual (instructions);

- elevator passport;

- installation drawing;

- schematic electrical diagram with a list of elements;

- basic hydraulic diagram (for hydraulic elevators);

- copies of certificates of compliance of safety devices with the requirements of TR CU 011/2011;

- act of checking the functioning of the modernized elevator;

- certificate of conformity assessment of a modernized elevator.

In addition, acts for hidden work and acts for electric welding work can be stored in the archive.

Requirements for the preparation of additions made to the operating manual and passport of the elevator being modernized are contained in clause 6.4.1.1 of GOST R 58495-2019. So, the following information is entered in the passport:

- about the work performed to modernize the elevator, including changes in the composition of elevator equipment;

- on supplementing the elevator operating manual with new accompanying documentation.

The specified information is entered into the elevator passport and certified with his signature by a representative of the specialized organization that carried out the modernization of the elevator (clause 6.4.2 of GOST R 58495-2019).

If at least one component of the old elevator is preserved when replacing elevator equipment, such work should be classified in accordance with the provisions of the CU TR as elevator modernization . Replacing an elevator involves a complete replacement of all its parts, without exception!

Maintenance fee

Citizens whose apartments are located on the 1st and 2nd floors pay monthly fees for the maintenance of the lift, although the majority consider this to be unfair. However, taking into account the provisions of the Housing Code, persons living on the lower floors are the same shared owners of common property as the owners of other real estate. Therefore, the fee for an elevator in an apartment building also applies to them.

It is theoretically possible to exempt this category of the population from paying monthly amounts for the maintenance of the lifting mechanism: the decision must be made by a majority vote at a general meeting of apartment building residents. However, in practice this is unlikely - it is unlikely that citizens will want to exempt their neighbors from participating in the costs of maintaining common property.

WE CONDUCT PERIODIC TECHNICAL INSPECTION AND INSPECTION

The assessment of the maintenance of the elevator in a technically sound condition, ensuring its safe operation, is carried out during its technical examination in accordance with the requirements of the Rules (clauses 4.1, 4.3 of the Regulations on PPR) after performing annual routine repairs. This assessment is carried out by specialists assessing the compliance of elevators with the safety requirements of an accredited testing laboratory. The period of technical examination for elevators put into operation cannot be less than once every 12 months (clauses 25, 26 of the Rules).

Technical examination

Technical examination is carried out in three steps (clause 3 of TR CU 011/2011):

After the technical examination, the employee of the organization that performed it draws up a report and makes an entry about it in the elevator passport.

Technical inspection

At the end of the elevator’s service life, a technical inspection is carried out, the purpose of which is to determine whether further operation of this elevator is possible. The assigned service life of the elevator is set equal to 25 years from the date of its commissioning[13].

It is prohibited to use elevators whose service life has expired without:

- conducting a survey;

- drawing up a conclusion on the compliance of the object with the conditions of its use[14].

The results of the examination are documented in the appropriate act.

The frequency of repair, maintenance and inspection of elevators, see table. 3.

If there are no funds for technical inspection, then the operation of the elevator must be stopped by stopping it.

As after installation of an elevator in connection with replacement or installation in a commissioned building or structure, so after modernization, the owner of the facility sends a notification to the authorized body about the commissioning of the facility.

Forced replacement

Restoration work or dismantling and installation of a new elevator is possible without taking into account the deadlines stated in the regional program. If money for major repairs is accumulated in a special account, in order to make a replacement, it is necessary to organize a meeting and put the issue to a vote. The decision will be positive if approved by a majority of votes. The application and the minutes of the meeting attached to it should be sent to the local housing and communal services department. If there is not enough money in the account, again at a meeting of owners it is decided how the difference will be repaid. You can increase your monthly payment or take out a loan.

WE ORGANIZE DOCUMENT FLOW

Naturally, at each stage of the elevator’s life cycle, documents are generated and must be stored, which is one of the responsibilities of the responsible persons. The requirements for the list of documents are established:

- paragraph 3 of Art. 3 TR TS 011/2011;

- clause 6 of the Rules approved by Decree of the Government of the Russian Federation dated June 24, 2017 No. 743;

- Section 1.8 of the Rules approved by Order of the Ministry of Energy of Russia dated January 13, 2003 No. 6.

First package of documents

The first package of documents for elevators and elevator safety devices put into circulation on the market is completed by the equipment manufacturer. This is the accompanying documentation, including:

- operating manual (instructions);

- passport;

- installation drawing;

- schematic electrical diagram with a list of elements;

- basic hydraulic diagram (for hydraulic elevators);

- a copy of the elevator certificate, elevator safety devices (taking into account clause 2.7 of Article 6 of TR CU 011/2011), fire doors (if any).

The operating manual (instructions) includes:

- installation instructions containing instructions for assembly, adjustment, adjustment, testing and inspection procedures;

- instructions for use and measures to ensure the safety of elevators during operation, including commissioning, intended use, maintenance, certification, inspection, repair, testing;

- list of quickly wearing parts;

- methods for safely evacuating people from the cabin;

- instructions for decommissioning before disposal.

Second package of documents

The second package of documents is completed by the owner of the elevator in the process of putting it into operation. This package includes:

- declaration of conformity of the elevator - for elevators or a certificate of conformity of the lifting platform for the disabled, passenger conveyor (moving walkway) and escalator with the requirements of technical regulations - for the lifting platform for the disabled, passenger conveyor (moving walkway) and escalator;

- an insurance policy confirming the conclusion of a compulsory insurance agreement for civil liability for damage caused by an accident at the facility;

- copies of the concluded agreement (agreements) with specialized organizations on the performance of installation (dismantling) work if they are concluded in accordance with clause 16 of the Rules and a copy of the technical inspection report of the lifting platform for disabled people, the passenger conveyor (moving pedestrian walkway) and the escalator in the form, approved in accordance with clause 25 of the Rules - for a lifting platform for the disabled, a passenger conveyor (moving walkway) and an escalator;

- certificates of control inspections and commissioning;

- registration notifications.

Third package of documents

The third package of documents is completed by the person responsible for electrical equipment in accordance with the requirements of PTEEP[15].

Also, the organization operating the elevator must adopt the following local acts on the appointment of persons responsible for organizing the maintenance and repair of the elevator:

- an order appointing persons responsible for organizing the operation of the elevator;

- a list of addresses of elevators provided by the customer and accepted by the contractor for maintenance, repair and modernization work;

- a list of addresses of elevators where, according to the contract, the contractor performs technical certification and electrical measurements;

- application for full technical certification;

- application for registration of a technical device;

- application, contracts and copies of documents on training of service personnel.

The responsibilities of the elevator owner also include the development of production instructions that take into account specific operating conditions and the requirements of the operating instructions of elevator manufacturers[16].

Causes of breakdowns of elevator equipment

The elevator production company “Steel Rope” has been servicing elevators and equipment for them for almost 20 years. In practice, we have encountered various causes of breakdowns, carried out restoration operations of any level of complexity and developed a conditional classification of the causes that result in the repair of elevators and equipment. They can be divided into three large groups.

- Failures associated with operating conditions. This is natural wear and tear or violation of load limits, high intensity of operation of devices, etc.

- Malfunctions caused by violation of operating rules (the largest group).

- Factory defects or installation errors are causes of breakdowns that do not depend on the user, but often provoke additional costs.

According to statistics, the parts in elevator mechanisms that are subject to maximum load most often break. These are braking systems, electronic units, gearboxes and their worm pairs, drive mechanism parts, counterweights, suspension components, supporting structures, cabin lining, etc. Almost any type of breakdown can be eliminated if elevator equipment is repaired in a timely manner.

Overhaul of elevators from LiftComfortService

The LiftComfortService company will carry out repair work on elevator equipment of any complexity. Our craftsmen have all the necessary parts and tools at their disposal at all times. A high level of preparation eliminates any waiting for missing elements and allows you to repair the elevator here and now. Our company not only restores elevator resources, but also performs system maintenance, which allows us to promptly notice and replace outdated and worn parts.

We will not only repair the elements of the mechanism, but also replace the finishing materials inside the cabin, and also equip the elevator with additional equipment and modern design shades that increase the level of safety and comfort. Find out the details of service, as well as everything about capital from the LiftComfortService company by calling.

Types of work on servicing elevator equipment

Since elevators are sources of increased danger, they are subject to increased requirements for the reliability of the materials from which they are made and timely scheduled and major repairs.

The simplest type of maintaining an elevator in working order is maintenance. In accordance with the specified regulatory documents (GOST R 54999-2012), the following types of services exist:

- TR – monthly;

- TR-1 – quarterly;

- TR-2 – six months;

- TR-3 – annual.

Any of the listed types of maintenance includes:

- cleaning elevator shafts from dust and debris;

- cleaning cabins from dirt;

- adjustment and lubrication of elevator cabin doors and floor doors;

- lubrication of cable blocks and rubbing (sliding) parts;

- replacement of worn-out units and parts;

- inspection (testing) for compliance with GOST and technical requirements for operational safety.

Do not apply to work performed in accordance with maintenance requirements . This is: daily cleaning of the elevator cabin - carried out by an employee of a cleaning company that has entered into an agreement with Management Company (TSN). Replacement of main parts - electric motor, winches, cables, elevator cabins, modernization of the electronic cabin control unit. These works fall into the category of preventative maintenance (PPR). When the service life of the main components and parts is completely exhausted, the elevator must be replaced with all equipment. This type of repair is a major one.

Who is responsible for the operation and repair of elevators?

It would seem that the elevator, although complex, is not such equipment as to assign several government services and monitor its performance. However, this is true.

- the production of elevator equipment is carried out by enterprises subordinate to Rosstandart;

- installation of passenger and freight elevators, as well as escalators, is supervised by Gosstroynadzor;

- Warranty and post-warranty maintenance of elevators is the responsibility of Rostechnadzor;

- The Housing Inspectorate and Management Company (TSN) are responsible for the operation and maintenance of elevator equipment in specific apartment buildings.

Each of the listed departments is guided by its own local regulations. But there is a document that all organizations that are, to one degree or another, involved in the production and operation of elevator equipment are required to adhere to. The document is called: TR CU 011/2011 (Technical Regulations of the Customs Union). It is entirely dedicated to elevator safety issues. In addition to the specified Regulations, operating organizations must be guided by the standard established by GOST R 54999-2012 (EN 13015:2001) “Elevators”, which establishes general requirements for the operation of this equipment.