What is a heat meter

A heat meter is a device for metering consumed heat.

With this device you can save your money, since you will not pay according to dubious standards, but only for the heat that you yourself consumed. No overpayments. How to choose the one that suits you among the many product models? It is important not to miss a single detail: assess the installation location, analyze the design of heating networks, study the installation features of an individual product, and enter into an agreement with a specialized company involved in servicing the device. Due to possible difficulties, some people do not dare to purchase a heating meter.

Despite the variety of models, differing in parameters and design, having advantages and disadvantages, the operating principle of an individual heating meter is the same. This is a product that measures the temperature, as well as the water flow at the inlet and outlet of the pipeline of a heating supply facility.

Removing and installing a heating meter

To repair a faulty appliance, the homeowner calls an employee of the service company and notifies the heat supply company. If dismantling is required to restore the heat meter, a report regarding this is drawn up with signatures from representatives of both companies. During complex repairs with complete replacement of faulty parts, a replacement device is installed in the heating riser.

An apartment heat meter is installed only in private houses with one owner or multi-apartment residential complexes with a collective metering unit. For the initial installation of a heat measuring unit, you need to hold a meeting of residents and choose the right company for installation and maintenance. Experienced licensed companies:

- develop technical design and installation plans;

- obtain the necessary permits;

- they will select devices for trouble-free operation on old pipelines;

- will carry out complex plumbing work (with cutting threads, installing additional taps, fittings, adapters);

- will enter into an agreement with residents for ongoing maintenance.

Composition of the heat meter

The composition of the heating meter is quite simple. Product includes:

- Heat calculator

- Flow sensor

- Temperature sensors

- Overpressure sensors

- Power supplies

The central component of the device is a heat calculator. The main advantages of these computers:

- Flexible setup.

- Convenient to use.

- Clear interface.

The computers are equipped with outputs for connecting a computer, modem or printer. This provides remote acquisition of data on heat consumption and coolant parameters.

Operating principle of the heat meter

The operating principle of an individual product is based on calculating the amount of heat using data received from a coolant flow sensor and two temperature sensors. The amount of water passing through the heating system is measured. The difference between the inlet temperature and the outlet temperature is also taken into account.

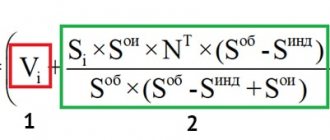

The amount of heat is calculated using the following formula:

Q = G * (t1 - t2), gCal/h, where:

- G—mass flow of water, t/h;

- t1,2 — inlet and outlet temperatures, °C.

The calculation receives all the data from the sensors. Then the received information is processed. After determining the heat consumption value, the computer records the data in the archive. The heat consumed is shown on the device display. It will not be difficult to take readings from the device.

Factors affecting the correct operation of the meter

Heat meters "Pulsar" are high-precision devices that operate with minimal error. However, there are several external factors that can affect the level of error. These include:

- thermal difference less than 3 degrees Celsius;

- disruption of water circulation in the pipeline, which entails a significant reduction in flow;

- violation of installation technologies (incorrect installation of temperature sensors, incorrectly set direction and other violations);

- low quality coolant (presence of large amounts of scale, high hardness);

- poor pipeline quality (contamination, corrosion).

If the difference in temperature conditions in the supply and return pipes is more than 3 degrees Celsius, the meter operates within the permissible error range. If the temperature difference is less than 3 degrees Celsius, the error may change upward. In this case, the device still operates in normal mode and calculates the consumption of thermal energy.

Heat meter accuracy and errors

No precision instrument is immune to errors. The heat meter was no exception. The total error when measuring heat consists of errors:

- Calculator.

- Thermal sensors.

- Flow meter.

The permissible error of heat meters installed in apartments is no more than 10%. However, this figure may be higher. The increase in real measurement error compared to the base one is influenced by the following possible factors:

- Incorrect installation that does not meet the manufacturer's requirements. This problem occurs especially often among people who have used the services of an unlicensed organization. In this case, the manufacturer does not assume any warranty obligations.

- The temperature amplitude at the inlet and outlet of the coolant does not reach 30 degrees.

- Poor quality pipes, hard water with mechanical impurities, which is used directly in the coolant.

- When the coolant flow is below the established minimum, which is recorded in the technical characteristics of the device.

Individual heat meters

Installation of an individual heat meter is not necessary. It is installed at the request of the apartment owner, as stated in the Decree of the Government of the Russian Federation dated 05/06/11 No. 354 (clause 3, article 33, section V).

According to the Order of the Ministry of Regional Development dated December 29, 2011 No. 627, individual meters are prohibited from being installed in apartments with vertical wiring.

In addition, in order for the calculations for heating to take into account the readings of apartment meters, they must be installed in each residential and non-residential premises of the apartment building along with a general heat energy meter.

More information about the types of individual heat meters and their purpose is contained in the material “Heat meters for heating in an apartment.”

How is heat consumed measured?

Heat consumed is measured in gigacalories (Gcal). This unit of measurement has been used for quite a long time. However, it belongs to the non-systemic category. Heat meters produced in European countries calculate the tariff for consumed heat in GigaJoules (SI system). Sometimes the generally accepted international non-systemic unit of measurement kWh (kWh) is also found.

There should not be any difficulties when calculating heating fees associated with differences in the measurement systems of resource supply organizations. Using a special coefficient, one unit of measurement can be easily converted to another.

How to convey testimony correctly

Although the heat meter has a simple and understandable interface, the owner of the device often faces the problem of transmitting readings. Some apartment users do not understand how the meter functions and how to read and send data from the display.

To avoid possible difficulties, you need to carefully read the product data sheet. The instructions provide answers to the most common questions, describe in detail the characteristics of the heat meter, as well as the subtleties associated with its maintenance.

There are several ways to take readings from a meter:

- If the heat meter has a liquid crystal display, then it is necessary to visually record the measurement data. To do this, it is important to go to the desired section of the menu using a special button.

- ORTO transmitter. It is included in the basic package of devices manufactured in Europe. Using this method, the user can transfer data on the operation of the heat meter to a computer, and also print them out if necessary.

- Radio module. This accessory is included in some devices. Using the wireless method, the radio module transmits data remotely. When the receiver enters the signal operating area, measurement data is recorded and transmitted to the resource supply organization. Often the receiver is mounted on machines that provide utility services. For example, when a garbage truck follows a given route, it collects readings from metering devices within range.

- M-Bus module. In some metering devices it is included in the delivery. The purpose of the M-Bus module is to connect the heat meter to the network of a centralized system for collecting readings by resource supply organizations. Using twisted pair cables, a group of heat meters is connected into a weak network. Next, they are connected to a concentrator, whose task is periodic polling. Then a report is generated, which is sent to the resource supplying organization. In addition, the data can be displayed on a computer screen.

Installation procedure for a collective heat meter

If the centralized heat supply system has the technical ability to install a common house heat meter, it must be installed.

In newly built houses, energy meters are installed before the facility is put into operation. This requirement is contained in the law on the installation of a common house meter dated November 23, 2009 in paragraphs 7-8 of Article 11, and paragraph 9 of Article 13 defines the area of responsibility for installing a public meter in houses where it is not available.

In order for a common house meter to appear in your home, you must go through several stages of its installation procedure.

- A meeting of owners of an apartment building (MKD) is the basis for the installation of heat meters for heating in an apartment building.

- The meeting may be initiated by the Management Company. In HOAs, housing cooperatives, and residential complexes, the meeting is held on the basis of an application from the owners; 10% of the signatures of the total number of votes is sufficient.

- Technical conditions for the installation of an ODPU, in accordance with which its design and installation will be carried out, are issued by the heat supply organization.

- The installation project and the estimate for the work are prepared by the design organization, taking into account the specific installation location and indicating the device model.

- Coordination of the project with the heat supply organization that issued the technical specifications.

- Purchasing a project-approved ODPU, mandatory with a verification stamp.

- Installation of ODPU and putting the meter into operation.

Find out in more detail how to install communal metering devices in apartment buildings.

Organizations responsible for installing ODPU

According to Law No. 261-FZ, the responsibility for installing a collective heat meter is assigned to the owners of apartments in a multi-storey building, who must carry out this activity independently, choosing an equipment supplier and a contractor for the work.

Assuming that there will be houses that are not equipped with ODPU, legislators determined who should install heat meters in this case. So, if on July 1, 2012, houses did not have a heat meter, the responsibility for installing it was transferred to the resource supply organization (RSO).

In addition, the RSO is obliged to prepare proposals for equipping apartment buildings with metering devices and carry out the corresponding work, which is confirmed in the letter of the Federal Antimonopoly Service of Russia dated December 8, 2011 No. AG/45584.

Thus, the widespread information that the management company installs heating meters is erroneous. The task of the management company is only to:

- bring to the attention of the owners of apartments in apartment buildings the need to install a collective heat meter;

- organize a meeting;

- draw up a protocol of consent.

Activities for installing the device can be carried out by heat energy supply organizations or specialized companies that have:

- Qualified specialists on staff of the company.

- Permission to perform the relevant type of work, issued by SRO.

Types of heat meters

There are the following types of heat meters:

- Tachometer or mechanical.

- Electromagnetic.

- Ultrasonic.

- Vortex.

Let's look at each type in more detail.

Tachometer or mechanical

The device, using a rotating part, measures the amount of coolant that has passed through the cross-section of the pipe. The active part of the device can be turbine, screw or impeller-shaped.

Tachometer heat meters have an affordable price. The undoubted advantage of the device is its ease of use. However, these metering devices also have significant drawbacks. Tachometer heat meters are extremely sensitive to contamination. Dust, dirt and rust often settle inside the mechanism. Cases of water hammer are also not uncommon. To reduce contamination of component parts, the manufacturer has developed a special magnetic mesh filter. Heat meters do not have the ability to save data collected per day.

Electromagnetic

The advantage of the heat meter is its high accuracy. A significant drawback is the high price. Composition of the metering device:

- Primary converter.

- Thermal sensors.

- The electronic unit.

The operation of an electromagnetic heating meter is based on the principle of a magnetic field passing through the coolant flow, which gives a reaction to its condition. The device requires careful care. An electromagnetic heat meter will not work with high accuracy without regular maintenance and periodic cleaning.

Ultrasonic

This type of metering device is used mainly as a general house heat meter. Among ultrasonic devices, the following subtypes are distinguished:

- Temporal.

- Frequency.

- Doppler.

- Correlation.

The specificity of ultrasonic metering devices is that heat meters operate on the principle of generating ultrasound that passes through water. The transmitter generates a signal. After the signal has passed through the water column, it is picked up by the receiver. The main condition for high accuracy and absence of errors of an ultrasonic heat meter is sufficient cleanliness of the coolant.

Maintenance of common house heat metering devices

Maintenance of the meter involves maintaining it in working condition. This is achieved as a result of preventive work, such as:

- inspection and elimination of causes affecting wear and breakdown of the control and measuring unit;

- checking the operation of additional equipment;

- operational maintenance and control of metrological accuracy of measurements of the metering device;

- weekly readings for analysis and development of recommendations for maintaining the required temperature.

If a malfunction is detected during the inspection, the device is dismantled, the damage is repaired and reinstalled.

To get a complete picture of maintaining the ODPU in working condition, find out how the MKD heating system is maintained.