The gas meter SGMN-1 G6 is a Belarusian-made membrane device used for measuring the volume of consumed gas fuel with non-aggressive properties. The product can be used by individual household consumers, commercial or municipal organizations, industrial enterprises for installation at facilities with a nominal hourly flow rate of up to 6 cubic meters.

Type of meter – SGMN-1 G6

Design and principle of operation

The device consists of the following parts:

- a steel body, including two halves connected by bolts with a sealed gasket;

- two measuring chambers with membranes;

- crankshaft with connecting rods;

- distribution spool system;

- counting block.

The movement of the gas mixture occurs due to the difference in pressure at the inlet and outlet of the apparatus. Alternately entering each of the chambers, the gas displaces the membranes. Redistribution occurs due to spools and a channel system. The membrane drives the crank mechanism, which rotates the components of the counting unit. The executive body that displays the readings is a roller display.

In some modifications, a pulse output with a sensor is built into the counter mechanism, which allows you to remotely transmit information about fuel consumption to a third-party device of a centralized system using accumulated pulses.

Verification interval

The calibration interval is the period during which the manufacturer provides a guarantee for the correct operation of the device.

The duration of the verification interval ranges from 8 to 12 years .

If it was not carried out on time or there is no new seal, the readings of this device cannot be taken into account for presentation for payment.

Verification must be carried out by special gas services . This procedure proceeds as follows:

- Call a specialist. It must be from the service with which the contract for the maintenance of gas equipment is concluded.

- Dismantling the meter and sending it for verification.

- Issuance of a conclusion based on the verification results. There may be two options: recognition of the measuring instrument as suitable or unsuitable. If suitable, the device is installed in place by a specialist and sealed. The date of verification is indicated in the passport.

If the measuring instrument is found unsuitable for further use, a certificate of impossibility of its use is issued for it. Its owner is informed about this.

You can learn how on-site verification of

Specifications

| Characteristics | Meaning |

| Medium to be measured | Natural gas according to GOST 5542-87, liquefied gas according to GOST 20448-90 |

| Maximum flow rate, Qmax, m.cub./h | 10 |

| Nominal flow, Qnom, m.cub./h | 6 |

| Minimum flow rate, , Qmin, m.cub./h | 0,06 |

| Maximum pressure, kPa, no more | 60 |

| Operating temperature, °C | -40… +60 |

| Relative error under normal conditions (20±3)°С, %, no more, at flow rates: | |

| From Qmin to 0.1 Qnom From 0.1 Qnom to Qmax | ±3 ±1,5 |

| Additional error caused by deviation of the temperature of the gas being changed from 20°C when the temperature changes by 1°C, %, no more | 0,45 |

| Pressure loss at maximum flow, Pa (mm water column), no more | 250 (25) |

| Sensitivity threshold, m.cub./h, no more | 0.002Qnom |

| Cyclic volume, dm. cube | 2 |

| Capacity of the reading device, cubic meters. | 99999,999 |

| Pulse output parameters: | |

| voltage, V, no more than current, mA, no more than price of one pulse, m.cub./imp. | 12 10 0,01 |

| Overall dimensions (length x width x height), mm, no more: | |

| version 1 version 2 | 307 x 165 x 223 265 x 165 x 243 |

| Weight, kg, no more: | |

| version 1 version 2 | 3,8 3,3 |

| Standard service life, years | 20 |

| Calibration interval, years | 8 |

| Price, increased rub. | from 3500 |

Gas meter SGMN 1 G6 - technical characteristics and advantages 2021

- Flow rate from 0.06 m³/h to 10 m³/h;

- Error in readings from -1.5% to +3%;

- Sensitivity threshold – 0.008 m³/h;

- operating pressure - 50 kPa;

- meter operating temperature from -40 C° to +50C°;

- The period between verifications is 8 years;

- Service life - 16 years;

- Service life - 20 years;

- Warranty period from the manufacturer - 1.5 years;

- weight - 3.3 kg or 3.8 kg;

- DN - 32 mm;

- coupling connection, parallel from above

- Flow rate from 0.06 m³/h to 10 m³/h;

- Error in readings from -1.5% to +3%;

- Sensitivity threshold – 0.008 m³/h;

- operating pressure - 50 kPa;

- meter operating temperature from -40 C° to +50C°;

- The period between verifications is 8 years;

- Service life - 16 years;

- Service life - 20 years;

- Warranty period from the manufacturer - 1.5 years;

- weight - 3.3 kg or 3.8 kg;

- DN - 32 mm;

- coupling connection, parallel from above

This device is most actively used in apartments and private houses.

It has convenient dimensions for installation, as well as an accurate and sensitive measuring mechanism. In addition to using the device for the home, it can also be used in industrial enterprises or in the housing and communal services sector (the throughput capacity allows this). The flow meter can monitor the consumption of almost any resource; the only limitation is that the gas should not be aggressive towards the materials from which the device is made. The two-chamber gas meter SGMN 1 G6 makes measurements using diaphragms. Gas, passing through the left or right inlet, enters a special chamber. As it fills the chamber, it moves the diaphragm. This translational motion is converted into rotational motion using a special mechanism. As a result of rotation, the meter readings change and resource consumption is recorded.

This mechanism, despite its simplicity, provides sufficient accuracy of readings. In addition, it is quite unpretentious in maintenance (the calibration interval is 10 years), and also rarely breaks down. This household meter can be used both indoors and outdoors. The operating temperature range is from -40 to +60 degrees Celsius. However, it must be remembered that the device does not have built-in temperature compensation, so when obtaining indicators, it is necessary to take into account the ambient temperature and make appropriate adjustments.

This gas meter is characterized by the following parameters:

- The capacity of the counting mechanism is 99,999 cubic meters.

- The nominal level of resource consumption for this device is 4 cubic meters per hour, the maximum level is 6 cubic meters per hour.

- The optimal pressure level in the system for controlling consumption using this device is 10 kPa, the maximum level is 50 kPa.

- The level of error in measurements is no more than 3%.

- Standard service life is 20 years, verification period is once every 10 years.

More complete parameters of the flow meter can be found by studying the technical data sheet of the device, which is supplied with it upon purchase.

The described metering device has the following advantages:

- High level of sensitivity of the device for monitoring the consumption of natural resources. It starts working even with minimal fuel consumption.

- Availability of a reliable case. This protects the measuring mechanism, firstly, from aggressive environmental influences and corrosion, as well as from unlawful actions in order to reduce resource consumption readings.

- The long interval between verification procedures allows the user not to experience any special problems in servicing the device.

- Only wear-resistant materials are used in the manufacture of the device. This allows you to significantly increase the service life and ensure the accuracy and correctness of measurements throughout its entire duration.

- Convenient dimensions make it easy and quick to install the metering device, and then use it to quickly monitor the level of resource consumption.

When deciding to buy a gas meter SGMN 1 G6, you need to pay attention not only to its advantages, but also to what its price is. The price of the gas meter SGMN 1 G6 is quite affordable for a wide range of users, but when purchasing, you should collect information about the availability of possible discounts or marketing promotions. It is quite possible to install this metering device on the most favorable terms.

It is recommended to trust the installation procedure of the device to professionals, since working with a gas system requires special permits, as well as knowledge and skills. Violation of technology and work rules can lead to serious consequences.

Thus, when deciding in favor of the described meter, you can be absolutely confident in its quality, optimal functionality, measurement accuracy and long service life.

The calibration interval for this meter is 8 years.

It is measured from the date of the initial (or last periodic) verification, which is indicated in the passport for this measuring instrument and is supported by the imprint of the verifier's stamp. The frequency of verification and the warranty period are in no way related. - more than a year ago

The last time we checked was in 2014, yesterday they came again i.e. in 2021 I bought the house in 2012 in these 4 years, this is already the second check of the passport for the meter after the old owners, but I found out from the brand of the meter that the frequency is at least 8 years. - more than a year ago

This is interesting: Installing an electricity meter in a private house: how to install it in 2021

Without a passport or at least without a Verification Certificate, you should not accept this meter for commercial payments. You need to either issue a duplicate passport and have it verified, or install a new meter.

Verification and verification are two big differences. They can come check at least once a month, if this is stipulated in the contract for the supply of the resource. - more than a year ago

Eight years since it was installed. And they can come with a check (from the comments) at any time. You should have asked them (since there are no documents) when the meter was sealed - this will be the beginning before the verification period.

It will work until verification and without documents, no problem. And then change it or do it when checking. They will just take it and make it late and you will pay (as in the region there are norms for this matter).

Due to the periodic increase in gas tariffs, an increasing number of citizens of the Russian Federation are installing gas meters within their living space. They can significantly reduce utility costs.

After all, payment at the average standard tariff is much higher than according to the indicators of the meter. After installing a gas meter, the owner should adhere to the correct operating conditions. You will also need to regularly monitor problems and carry out timely verification, repair and replacement of equipment.

Gas meters are special devices designed to record the consumption of natural or liquefied gas. The types of such devices are presented in the table.

The main characteristic of gas meters is their throughput. This indicator allows you to determine how much of a resource can pass through the counter within a certain time. This number is indicated in the device labeling.

For example: if G4 is written on the meter, this means that its throughput is 4 m 3 / h. The installation of the device must be carried out in a system within which the total demand for “blue fuel” of all household devices located there does not exceed the indicated indicator.

Another important feature of each device is the total duration of its operational period. The average service life is 20 years or more. The countdown is carried out not from the moment the meter is installed, but from the date of manufacture at the factory.

The calibration interval is the period during which, according to the manufacturer’s warranty, the metering device will be able to function smoothly and error-free. This period is necessarily indicated in the passport for the device (for gas meters it is often 8-12 years).

Verification is carried out by employees of the gas service (Gorgaz). To do this, the owner of the metering device needs to call a specialist from this structure, who will dismantle the meter. Next, you should deliver the device to a specialized center for verification, then pick it up along with the final report on the procedure, again call specialists who will install and seal the device, if it is in working order.

The date of the next verification must be counted from the moment the meter is installed in place after the previous such procedure. If the device is not suitable for further use, the owner will need to replace it.

If you violate the recommended operating conditions, the meter will most likely break prematurely. To avoid unwanted consequences, you need to take care of:

- correct installation of the device;

- presence of a dust filter;

- correct choice of device throughput;

- absence of excessive air humidity in the room where the meter is installed.

If you provide the device with ideal operating conditions in accordance with the instructions, you can achieve maximum service life and error-free operation.

The most common deviations in the operation of gas meters are:

- fragmentary presence of an image on the screen or its complete absence (for electronic metering devices);

- stopping the counter (for all models);

- gas leak in the area where the device is mounted (for all models).

If a malfunction of the device is noticed by a representative of the gas company, he will draw up a report on the existence of this fact, according to which its owner will have to pay the recalculated amount for the last 6 months for gas (not according to the meter readings, but according to the average regulatory tariff developed for those consumers who do not have a metering device in their house/apartment). A notification of recalculation indicating the new amount will be sent to the meter user's address within an interval of 1 month.

Today we will look at the popular Belarusian-made gas meter SGMN-1 G6.

The meter is designed to keep track of gas consumption. The gas that the meter counts should not be aggressive. The meter is most often used in the housing and communal services and household segment.

The gas meter model SGMN-1 G6 can be either with a left or right gas inlet.

The distance between the inlet and inlet pipes can be 200 and 250 mm. If you need a counter with a distance of 250 mm, then they only come on the left. If you choose the left counter instead of the right one, then during installation you will have to turn the counter side forward and it will turn out that the score board will be turned away from you.

In addition to the distance between the inlet and outlet tubes, the meters differ in the diameter (DN) of the thread and nut (it can be 25 mm and 32 mm). On meters marked SGMN, the nut diameter is always DN 32mm.

- Meter type - membrane

- Average operating gas consumption 6m3 per hour

- Maximum volume of gas passed 10 m3/hour

- Dimensions for installation: 306x165x223mm

- Used at ambient temperatures from -40 to +50

- Maximum operating pressure - 60 kPa

This is interesting: How to pay for gas using a meter, how to calculate payments for 2021

The calibration interval for the gas meter SGMN-1 G6 is 8 years.

This means that you must check the meter every 8 years to detect any breakdowns or incorrect counting. Verification of the gas meter can be carried out either on site or by removing it and delivering it to the gas management organization. It is also important to have a meter passport, since without it you are unlikely to pass verification.

Meter Neva MT-124 - taking readings

The minimum service life of SGMN-1 G6 is 20 years. During this time, you can undergo verification several times. The verification is paid, so if it turns out that the device is faulty, in addition to the costs for verification, the cost of purchasing a new gas meter will be added.

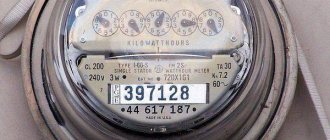

To take readings from the gas meter SGMN-1 G6, let's look at the drum dial, which has 8 digits (digits). The first 5 from left to right before the decimal point count the number of whole cubes of gas, and after the decimal point the numbers highlighted in black or another background count fractions of cubes.

Due to the poor degree of protection from the effects of magnetic fields, many people purchase neodymium magnets and stop the rotation of the counting mechanism in order to steal gas and reduce the readings on the meter. Stopping the SGMN-1 G6 meter with a magnet is illegal, like any other gas meters.

For such actions, a fine may be imposed on the owner, which will be many times greater than the saved cubic meters of gas. Now the new type of meters are produced with an anti-magnetic seal. SGMN-1 G6 meters with remote control are also modified to manipulate readings and stop the meter; they are also illegal.

Prices Buy a gas meter SGMN-1 G6 in Russia for different regions at different prices. The average cost ranges from 3,300 rubles to 4 thousand rubles.

Payment for gas is made in two ways: a fixed amount per month or according to the volume consumed.

The second option turns out to be more profitable; for this you need to install a gas meter. A good option would be the Belarusian gas meter sgmn 1, it is of high quality and affordable. The device is ready to work with non-aggressive types of gas.

At a low price, the gas meter sgmn 1 g6 has parameters due to which it is in demand in the household segment and public utilities, as well as in manufacturing enterprises. The characteristics of the equipment are indicated in the passport, here are the significant ones:

- verification period - 10 years;

- the manufacturer promises a service life of several decades;

- working pressure 50 kPa;

- error no more than 1.5% at maximum throughput;

- maintaining performance characteristics in the temperature range from -30 to +50 degrees Celsius.

The gas meter sgmn 1m does not require special maintenance and maintains its characteristics throughout its entire service life.

Belarus produces high-quality metering devices that can be purchased at attractive prices.

The product has a two-chamber design, which ensures accuracy of readings with a deviation of less than 1.5%. The operating principle is characterized by simplicity. The gas flow enters a two-chamber tank, where it forces the membranes to move; the amplitude of the movement through the interaction of a number of mechanisms causes the readings on the meter to change.

The demand for the sgmn g6 gas meter is due to the combination of affordable price and excellent technical characteristics. The simple and effective operating principle of the device helps you pay for utilities as much as you consume. The price of gas is constantly rising, so accurate gas meter readings are important for consumers who do not want to overpay for excess volume.

This model proves that you can purchase decent quality equipment at a low price.

The advantages of a Belarusian-made gas meter apply to both public utilities and end consumers of services. Both parties are interested in the high-quality operation of the metering device, which helps to achieve mutual trust. The following advantages should be highlighted:

- service life from 20 years;

- high accuracy of readings (minimal error);

- absence of noise during operation;

- maintaining operation in the presence of all kinds of contaminants in the gas;

- resistance to corrosion and other negative environmental factors.

The product passport contains a description of one part that will not be very appealing to those who like to cut costs by interfering with the normal operation of the meter.

In order to pay less on utility bills, some try to rewind the readings or pause the meter for the duration of full consumption. The price of fuel is high, but this is not a reason to violate the contract with the supplier and the current legislation. The design provides protection against interference with the operation of the equipment; attempts to change the indicators will lead to damage to the device, and utility services will be forced to pay a fine.

Using this model to accurately transmit readings becomes the best option with a suitable price.

The verification period of 10 years helps you not to think about additional actions for a long time after installing the device. The equipment is available in two versions, for right and left supply; before purchasing, it is worth checking the required type of model. The low price makes the purchase possible even if there is no budget for home renovation or individual equipment.

This is interesting: Reprogramming electricity meters 2021

Still have questions? Find out how to solve exactly your problem - call right now:

Gas meter sgmn 1 g6 Link to main publication

Apartment meter Vector-S-1.6

The VECTOR-S-1.6 inkjet small-sized gas meter is a household model in the most popular standard size. Its main competitive advantages over similar meters: a) self-diagnosis: indication of a failure or low battery b) readings are recorded in non-volatile memory every 2 cubic meters. As a consequence, the maximum loss of readings when the battery is dead (or replaced) is 1 cubic meter = 4 rubles. c) dust filter d) service life of the meter components is 20 years (the battery, LIKE EVERYONE, is 10 years) 2. for a gas volume temperature corrector (HELIOS-T) - all other things being equal, it is SIGNIFICANTLY lower in cost than competitors’ models. 3. membrane meters with an electronic reporting device (model with index T) are equipped with an ELECTRONIC gas correction BOARD, while competitors equip their models with a mechanical thermal corrector. The measurement accuracy of the device—its main purpose—is increased!

Gas meter Grand-1.6

The operating principle of the meter is based on the dependence of the oscillation frequency of the measured medium jet in the sensitive element of the flow meter on the volumetric gas flow rate. An auto-generator of jet pulses is used as a sensitive element, the frequency of which is directly proportional to the volume flow flowing through the meter. The oscillations of the jet are perceived by a piezoelectric sensor and converted into an electrical signal entering the electronic unit. In the electronic unit, the signal coming from the piezoelectric sensor is converted into a frequency signal linearly proportional to the volumetric gas flow rate under operating conditions.

The meter has an LCD display that displays the accumulated volume of gas that has passed through it.

The meter is powered by a lithium battery, which ensures continuous operation of the device for 12 years from the date of manufacture.

The gas meter has the following modifications:

- — without temperature compensation with pulse output;

- — without temperature compensation with pulse output and RS 232/485 interface;

- — with electronic temperature compensation and pulse output;

- — without temperature compensation with pulse output and RS 232/485 interface;

Advantages

- — the meter is installed in both horizontal and vertical positions (the indicator can be rotated to any position);

- - has no moving mechanical parts;

- — quick installation (no gas welding required);

- - affordable price;

- — manufacturing with heat compensation;

- — there is a pulse output for connecting telemetry;

- — there is an interface: 232/485;

- — minimum overall dimensions;

- — wide choice of color palette;

- — interverification interval is 12 years.

Gas meters VK G1.6; 2.5; 4

Purpose: household diaphragm gas meters are designed for commercial metering of the volume of gas consumed. Medium: natural, liquefied, petroleum and other dry, non-aggressive, non-uniform gases. Scope of application: accounting for the volume of gas in houses equipped with gas stoves, gas water heaters, and low-power heating boilers. The principle of operation of diaphragm meters is based on the alternate displacement of gas from the working chambers due to the alternate movement of diaphragms (partitions separating the working chambers) by the inlet gas pressure. The movement of the diaphragms through a system of levers and a gearbox activates the counting mechanism. Distinctive features: Household gas meters of the VK series implement a huge experience and knowledge of Kromshroder engineers in the field of gas measurement, accumulated over many decades. Low noise level, minimal wear and low pressure loss are achieved by the design features of the kinematic design of the meter. High measurement accuracy and high sensitivity are ensured by the use of shape-stable synthetic diaphragms and high-precision distribution valves. Insensitive to contamination and high corrosion resistance are ensured by the use of

high-quality materials for the manufacture of parts, assemblies and the use of special coatings. Possibility of use in automated systems for collecting information via radio channel, GSM channel, using a portable reading device. For remote transmission of information, a low-frequency pulse sensor (reed switch) type IN-Z61 can be connected to the meter, triggered by a magnetic insert built into the low-order digit of the counting mechanism. The combination of all features determines the long-term reliability of a diaphragm gas meter. Gas meters BK G4T Scope: Purpose: the meters are designed for commercial accounting of the amount of gas consumed. Measured medium: natural gas, propane, butane, inert gases and other non-aggressive gases of heterogeneous chemical composition. Scope of application: in public utilities, household gas meters NPM G1.6; 2.5; 4

The stability of the metrological characteristics of the meter throughout its entire service life has been proven by life tests Built-in backstop High-quality anti-corrosion coating Resistance to pressure surges in the network Optionally equipped with adapters, mesh filters, and verification methods The stability of the metrological characteristics of the meter throughout the entire service life has been proven by life tests. Built-in backstop. High-quality anti-corrosion coating Resistant to pressure surges in the network. Upon request, it is equipped with adapters, mesh filters, and verification methods. Specifications

»

Counters

Gas meter with thermal corrector: features of choosing a meter in 2021

Read more

Counters

How to calculate water using a meter? 2021

Read more

Great article 0

Advantages of the device

The meter is characterized by the following positive qualities:

- low measurement error;

- reliable and simple design;

- inexpensive prices for products;

- long service life;

- reliable protection against corrosion and temperature influences, allowing for external installation of the gas meter;

- the ability to select a model, depending on the direction of gas supply, with different center distances of inlet and outlet pipes;

- convenience and ease of reading information;

- attractive appearance;

- full compliance with Russian and international standards allowing the use of products on the territory of the Russian Federation;

- possibility of remote data monitoring (for modifications equipped with a pulse output).

Types of gas meters and their characteristics

Gas meters are special devices designed to record the consumption of natural or liquefied gas. The types of such devices are presented in the table.

| Based on throughput | Based on the operating principle |

| Household | Turbine |

| Rotary | |

| Utilities | Diaphragm |

| Industrial | Membrane |

The main characteristic of gas meters is their throughput. This indicator allows you to determine how much of a resource can pass through the counter within a certain time. This number is indicated in the device labeling.

For example: if the meter says G4, this means that its throughput is 4 m3/h. The installation of the device must be carried out in a system within which the total demand for “blue fuel” of all household devices located there does not exceed the indicated figure.

Another important feature of each device is the total duration of its operational period. The average service life is 20 years or more. The countdown is carried out not from the moment the meter is installed, but from the date of manufacture at the factory.

Types of counter

Taking into account the direction of gas supply, the distance between the inlet and outlet fittings and the presence of a pulse sensor, the products are manufactured in the following modifications, with the designation in the marking after SGMN:

- 1 – 1 – 1 – with a distance between pipes of 250 mm and a left-handed entrance;

- 1 – 1 – 2 – differs in gas supply on the right side;

- 1 – 2 – 1 – the entrance is located on the left, but the distance between the inlet and outlet pipes is 200 mm;

- 1 – 2 – 2 – similar model with right input;

- 1I – 1 -1; 1I – 2 – 1; 1I – 2 – 2 – correspond to the versions noted above, the difference is the presence of a pulse output.

Pulse output

The presence of a pulse output allows you to remotely transmit readings to a third-party device. A reed switch type sensor is used, which reacts by closing to the periodic influence of a weak magnet built into the wheel of the counting unit. One short circuit that creates a pulse is equal to 0.01 cubic meters of gas consumed. With increasing fuel consumption, the frequency of transmitted pulses increases.

Pulse output verification is not provided, and in case of differences in readings between the specified sensor and the counting device, priority should be given to the data on the gas meter display.

Verification

carried out in accordance with GOST 8.324-2002 “GSI. Gas meters. Verification method", in the presence of a pulse output, verification of meters is carried out according to MRB MP 1778-2008 "Gas meters SGMN-1, SGD-1, SGD-3T. Verification methodology”, approved by BelGIM in March 2008.

The main verification equipment is shown in Table 4.

Table 4

| Name of measuring instrument | Technical characteristics of measuring instruments used | Accuracy class, measurement error |

| 1 Gas meter testing complex | Air flow measurement from 0.002 Onom to Omax | from Omin to 0.10nom - ±1%, st. 0.10nom to Omax - ±0.5% |

| 2 Stand for testing strength and tightness | Creation of excess pressure from 0 to 0.1 MPa (pressure inside the meter under test is not less than 1.5 times the highest excess pressure) | |

| 3 Pressure gauges type MO | Measurement of excess pressure up to 0.1 MPa | Accuracy class 0.15; 0.25 |

| 4 Barometer | Barometric pressure measurement up to 106.4 kPa | No more than 133.32 Pa |

| 5 Laboratory thermometers | Temperature measurement from 0 to 600C | Division value 0.1 0С |

| 6 Liquid micromanometers | Pressure loss measurement from 0 to 300 Pa | Accuracy class 1.0 |

| 7 Psychrometer | Relative humidity measurement from 10 to 100% | Division price 0.5% |

| 8 Liquid pressure and vacuum gauges | Pressure loss measurement up to 2400 Pa | Measuring range 0 to 2400 Pa Accuracy class - 1.0 |

| 9 Stopwatch-timer | Measuring time, number of pulses | Permissible value limit errors in measuring time intervals at (20 ± 5) 0С ± (15 x 10 -6 x T + C), where T is the interval value in seconds, C - 0.01 at a division price of 0.01 s |

Taking readings

The roller display consists of 8 wheels, 5 of which, located on the left, indicate the whole amount of gas volume in cubic meters (blue rectangle), 3 on the right indicate the fractional component not used when taking data (red rectangle).

Taking readings from the meter – SGMN-1 G6

Sequence of taking gas meter readings:

- The current value of the whole number of cubic meters is recorded, without taking into account the leading zeros.

- The result of the previous reading is subtracted from the data.

- The resulting value is multiplied by the cost of one cubic meter.

Advantages of the device

The demand for the sgmn g6 gas meter is due to the combination of affordable price and excellent technical characteristics. The simple and effective operating principle of the device helps you pay for utilities as much as you consume. The price of gas is constantly rising, so accurate gas meter readings are important for consumers who do not want to overpay for excess volume.

This model proves that you can purchase decent quality equipment at a low price.

The advantages of a Belarusian-made gas meter apply to both public utilities and end consumers of services. Both parties are interested in the high-quality operation of the metering device, which helps to achieve mutual trust. The following advantages should be highlighted:

- service life from 20 years;

- high accuracy of readings (minimal error);

- absence of noise during operation;

- maintaining operation in the presence of all kinds of contaminants in the gas;

- resistance to corrosion and other negative environmental factors.

The product passport contains a description of one part that will not be very appealing to those who like to cut costs by interfering with the normal operation of the meter.

In order to pay less on utility bills, some try to rewind the readings or pause the meter for the duration of full consumption. The price of fuel is high, but this is not a reason to violate the contract with the supplier and the current legislation. The design provides protection against interference with the operation of the equipment; attempts to change the indicators will lead to damage to the device, and utility services will be forced to pay a fine.

Using this model to accurately transmit readings becomes the best option with a suitable price.

The verification period of 10 years helps you not to think about additional actions for a long time after installing the device. The equipment is available in two versions, for right and left supply; before purchasing, it is worth checking the required type of model. The low price makes the purchase possible even if there is no budget for home renovation or individual equipment.

Still have questions? Find out how to solve exactly your problem - call right now:

8 ext. 766 (Moscow)

8 ext. 420 (St. Petersburg)

8 ext. 398 (Regions)

It's fast and free!

Gas meter sgmn 1 g6 Link to main publication

Sources:

- www.bolshoyvopros.ru

- webrieltor.com

- schetchik-info.ru

- okommunalke.ru

Is it possible to save money?

The design of the device uses non-magnetic alloys and synthetic materials, which exclude unauthorized influence on the mechanism in order to reduce the actual volume. An additional guarantee for monitoring the use of the device is the presence of a pulse output.

The consumer saves by the very fact of installing a gas meter, given that the amount according to the standards will be much higher than the payment for the actual volume of gas used.

The use of an individual meter forces the consumer to take measures to save gas fuel consumption:

- thrifty attitude and consumption of energy resources;

- monitoring the tightness of connections;

- installation of economical gas-consuming appliances and turning to alternative methods of energy supply.