Situation 2: Dacha plot (SNT)

With the repair of roads in garden non-profit partnerships (SNT), the situation is much simpler. Those that lie within the SNT are property of common use of all its members and at the same time common property. This means that land owners must maintain roads and maintain their condition on their own.

What to do?

The decision to organize repairs is made at a general meeting, which is held once a year. Members of the partnership discuss the method of repair, after which responsible persons are appointed who will oversee the collection of funds and the implementation of the work itself. It doesn’t matter what you use to fill the road with – crushed stone, asphalt chips or sand. There is also no need to obtain special permits from the municipality for this. Everything is limited only by imagination and the funds allocated in the SNT budget. And, of course, building codes should not be neglected.

| SNiP 30-02-97* Planning and development of territories of gardening dacha associations of citizens, buildings and structures (with Amendment No. 1) 5.7* On the territory of a gardening (dacha) association, the width of streets and passages in the red lines should be, m:

|

What's the catch?

Difficulties can arise only if the section of the road inside the SNT belongs to the municipality or a private person. Before starting repair work on such a site, it is necessary to obtain the consent of the owner. It is unlikely that officials from the local administration will have any complaints if you patch up road potholes without spending a single budget ruble. But a private owner can easily bill SNT for damage to his property.

Expert opinion

Sergey Kolomiets, legal lawyer:

“Any owner has three main powers: use, possession and disposal. He maintains his property in the form in which he likes. If he wants, he will park the car or pave it, or even dig a pond on the site. Here you need to proceed from a specific situation and find out how it happened that a public road became private property. SNT participants will either have to negotiate with the owner about repairs or resolve the issue through the courts.”

Laying asphalt. How to pave the yard with your own hands.

Below is an algorithm of the required actions.

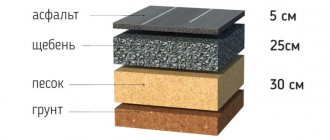

Stage one. First, excavation work is carried out, which consists of cleaning and leveling the base. To remove the top layer of soil, you can use a bulldozer or a regular shovel.

Stage two. The plan is marked out - a detailed diagram of the paths and passage for the car is drawn. In other words, the contours of the asphalt are drawn. By the way, if you are interested in asphalt paving in Moscow, we recommend following the link for detailed information. But let's return to our question.

Stage three. The mixture of gravel and sand is compacted and rolled.

Stage four. Various fences and curbs are installed.

Stage five. Asphalt is poured, after which it is compacted and rolled up.

The asphalt mass should be poured onto the prepared base in several large piles. This is necessary so that the asphalted area is distributed throughout the yard as much as possible. Then the mass is scattered with shovels and evenly distributed with a thickness of 5 cm to 10 cm. All unevenness is leveled using a mop-mop. If there are transverse slopes, asphalt rolling is performed from the bottom up. It will be much easier to enlist the support of assistants.

Note! All this must be done quickly, otherwise the mass will harden. Therefore, at least several people should be involved in the work. Also, the roller must not stop in one place, otherwise the total weight of the roll will increase.

That's all. For a more detailed introduction to the process, we recommend watching the thematic video below. Good luck!

The main advantages and disadvantages of asphalt pavements

- optimal price-quality ratio due to the low cost of materials used;

- simple asphalt laying technology that allows you to do the work yourself;

- speed of covering even large areas compared to the installation of concrete or prefabricated paving slab structures. Installation is completed in a few hours;

- ease of repair of damaged fragments

- when framing areas, paths, flower beds with small borders, a beautiful and aesthetic appearance of courtyards is obtained;

- waterproof coating

- sufficient strength, reliability and durability when properly executed;

- asphalt paving at the dacha will not allow weeds to grow through the coating;

- the possibility of using specialized technical means;

- ease of maintenance, in the summer it is enough to sweep away the debris with a broom and wash the surface with a regular garden hose, and in the winter it is convenient to remove snow on a flat surface.

- characteristic odors emanating from asphalt in the heat, especially in the first time after paving the site, which is due to the presence of bitumen components that emit unpleasant odors when heated, creating a certain discomfort;

- yard areas are mainly compacted with hand rollers, which does not ensure high strength of the upper layers. As a result, asphalt heated by the sun's rays can become deformed under the weight of heavy vehicles;

- difficulty when it is necessary to deliver small volumes of asphalt mixture to the site for fragmented repairs. Most suppliers may refuse this due to lack of profitability;

- inability to compete in beauty of appearance with expensive coatings.

This is interesting: Law on the local area of a private house

Asphalting of the local area

› Article current as of: October 2021 A well-kept yard is not only pleasing to the eye.

Rational paving of the local area of an apartment building ensures cleanliness in the entrance.

Covered areas of sidewalks and driveways reduce the amount of dust in the air. This indicator is especially important for small residents and allergy sufferers.

How to cover the local area with asphalt? Who pays for expensive work?

What do residents need to do to ensure that the coating lasts a long time and does not “fall off” along with the snow?

These questions are relevant for many owners.

Residents of apartment buildings must learn the main legal norm: taking care of their property, and this includes the local area included in the cadastral passport of a residential property, falls entirely on their shoulders.

We'll tell you how to get your yard in order.

This is a requirement of the Housing Code. The algorithm of actions includes seven steps: A working (initiative) group of residents of a high-rise building is created, which encourages the inert mass of residents to take action with the idea of paving the sites. At a meeting in person or in absentia, the majority favorably perceives the neighbors’ proposal.

The proposal is submitted to the management company.

An estimate is drawn up. A special account is opened for the work. A contractor is selected who will asphalt the house on a contractual basis.

Who pays and repairs?

Just a few years ago, all areas that belonged to an apartment building and the facilities located on them (playground for children, basketball/football field, horizontal bars, etc.) had to be looked after by housing and communal services companies.

However, not so long ago amendments to the Housing Code were adopted, which affected Article No. 158. Now all citizens living in the house must finance the process of improving the courtyard area. That is, payment for such work is transferred to the residents. In addition, they must pay for repair services performed by the management company’s specialists, including asphalt paving of the local area.

The first paragraph of the above article states that the material part of the issue related to laying asphalt is resolved by residents. They can form a special fund for this purpose by collecting monthly contributions from the residents of the house. In addition, it is advisable to first submit an official appeal to the director of the management company with a request for help in solving the problem. If there are unallocated financial resources and the necessary road equipment, management company employees will be able to lay asphalt pavement (or pothole repair) on their own.

It is definitely worth concluding an agreement with contractors, clearly recording the details of payment and the conditions for delivery of the finished work.

Nobody forbids residents to follow the procedure or make adjustments. If the services are provided improperly, then you can demand a reduction in fees. In the event of a controversial situation, based on the agreement, it is worth filing statements and complaints to higher authorities (housing inspectorate, prosecutor's office, court).

What does asphalt paving work include?

As soon as the management company draws up an estimate and submits it to the residents for consideration, the latter will be able to familiarize themselves with the list of work that will be carried out by the contractors. Here is a list of standard actions that the vast majority of apartment building residents order:

- Laying asphalt around the perimeter of the structure. The width of the canvas is 1 meter, starting from the walls;

- Asphalting areas near entrances (width - about 5 meters);

- Covering parking lots where residents’ personal vehicles are located;

- Improvement of areas for sports and children's entertainment.

This is interesting: Choosing a legal address for an LLC

Despite the listed values, people can indicate their preferences in the contract, having previously agreed on them with the management company, so that the wishes do not lead to any disruptions in the functioning of engineering systems.

Composition and types of asphalt concrete

Asphalt concrete is an artificial material obtained by rational selection of mixture components and its compaction after laying. Depending on the incoming components, the ratio of their mass parts and physical characteristics, there are many types of asphalt, divided into brands and types.

The composition of any asphalt concrete includes:

- mineral powders obtained by crushing rocks with a high content of carbon compounds (limestone or other fossilized organic deposits). The high content of such powders gives the material increased viscosity combined with strength. The property of such mixtures to dampen internal vibrations of structures without the formation of cracks in the coating allows the construction of road passages on road bridges. Successfully used for paving roads and sites

- bitumen, contained in most types in small quantities (from 4 to 5%). The exception is cast mixtures containing ≥ 10% bitumen. Bitumen gives the mixture increased fluidity, facilitating its distribution over the coating area, and elasticity after compaction and hardening. The main use of cast asphalt is paving of areas with complex terrain and repairing road surfaces. Increased bitumen content is used for asphalts laid in harsh climatic zones, at low temperatures and the need to open traffic immediately after the completion of a section of road or bridge crossing;

- sand is used in most types of asphalt concrete, the only exception being mixtures with a high gravel content. Natural sands are thoroughly cleaned, while artificial sands, obtained by crushing rocks, are immediately ready for use;

- crushed stone or gravel, which plays the role of a protective component that forms the asphalt concrete frame to absorb significant loads.

Based on the content of fillers, the following types are distinguished:

- A - from 50 to 60% crushed stone;

- B - 40...50% crushed stone or gravel;

- B - gravel or crushed stone from 30 to 40%;

- G - sand or screenings from crushing ≤ 30%;

- D - content of natural or artificial sands up to 70%.

Depending on the largest sizes of mineral grains in the mixture, they are divided into the following classes:

- coarse-grained first class - ≤ 40 mm. Used for paving highways with heavy traffic of heavy-duty vehicles and other highways of different classes;

- second class - with small grains ≤ 20 mm. Installed on pedestrian streets and squares;

- third - sand mixtures with grains ≤ 10 mm. Small fractions of grains are in close contact, which allows you to create perfectly smooth surfaces. The main purpose is pedestrian sidewalks, garden paths, improvement of courtyard areas and sports grounds.

The second brand is most widely used in asphalting roads, their repair and arrangement of private courtyards with the construction of transport entrances.

Depending on the laying temperature, asphalt mixtures are divided into 2 types:

- Hot, laid with a temperature of ≥ 110 degrees. The hot mixture is transported by special transport, called Kocher, or in dump trucks with a heated body. If necessary, preparation for asphalting is carried out by softening the base under the influence of high temperatures. After leveling, the mixture is rolled with rollers. The resulting durable coating is most widely used in road work and landscaping of urban and suburban areas;

- Cold ones, which are placed with temperatures ≥ 5 degrees. When preparing, bitumen with a reduced viscosity is used, which allows the mixture to remain in a loose state for a longer time, and after rolling it hardens faster. Most often, such asphalt concrete is used for pothole repairs, laying on sidewalks and courtyard driveways that are not subject to intense loads.

Any high-quality asphalt concrete can only be made from certified materials, therefore, when ordering, you must require quality certificates and a passport for asphalt concrete.

Types of asphalt for the yard. What asphalt to use

It is a multicomponent mixture based on sand, stone and bitumen binder.

We recommend reading: Where to see a narcologist and psychologist for weapons testing in Vyborg

The “correct” name of the material is asphalt concrete, which does not prevent the term “asphalt” from being used even in specialized publications. Asphalt consists of bitumen, sand, types of crushed stone or gravel, as well as mineral additives and fillers.

The only constant component is bitumen, and the remaining components can be added in different proportions.

Sand, contained in asphalt, plays the role of filler and fine base, helping to distribute pressure from the road to the ground. Without sand, the bitumen binder would leak out and crushed stone would be squeezed out onto the top.

In the case of special asphalts containing cement, sand participates in the cementation process and gives the coating additional hardness.

Mineral filler is a rock (sandstone, limestone or chalk) crushed to a dusty state, intended to fill residual voids.

Sandstone is the most versatile, as it is inert to almost any chemical attack. Calcium carbonates (limestone and chalk) are typically used on public roads, while sandstone can be used near chemical plants. Rubber – added to asphalt in the form of rubber crumbs (1-1.5 mm), it gives the coating high water resistance and plasticity.

Asphalts treated with rubber are much less likely to crack, which increases the period between repairs. The disadvantage of such roads is their high cost, so their use is limited to laying the most critical sections of highways.

Asphalt: types and classification

Asphalt is a finished road surface made from asphalt or asphalt concrete mixture. Asphalt or asphalt concrete mixture is a ready-made mixture of bitumen with mineral materials: crushed stone or gravel, sand (possibly with the addition of mineral powder). Asphalt is used for making road surfaces, for waterproofing, as a roofing material, and for making putties, adhesives, and varnishes.

The highest quality asphalt is used in painting and in the creation of lithographs.

Asphalt can be of natural and artificial origin: in natural mountain asphalt there is 60-75% bitumen, in artificial - 13-60%. Asphalt is often called asphalt concrete - an artificial stone material that is obtained by compacting asphalt concrete mixtures.

Classic asphalt concrete consists of crushed stone, sand, mineral powder (filler) and bitumen binder (bitumen, polymer-bitumen binder; tar was previously used, which is not currently used). COARSE-GRAINED – for the lower layers of two-layer asphalt concrete pavements. FINE-GRAIN – for the construction of main federal roads and streets with high traffic intensity.

SAND – for pedestrian paths and sidewalks, car parking areas, retail areas. MIXTURES WITH POLYMER-BITUMEN BINDING - to increase the durability of coatings. MIXTURES WITH RUBBER-BITUMEN BINDING (BITREK).

MIXTURES WITH UNIREM MODIFIER. RUBBER-ASPHALT CONCRETE MIXTURES – coatings of reduced rigidity, for example, for covering stadiums and running tracks.