Caring for the local area requires constant attention, time, and money. I often want to have a terrace, but wood outside is a real hassle. Too much time and money must be invested to maintain a normal appearance. There is an alternative - decking boards made of wood-polymer composite (WPC). Looks like board, no need to paint. By the way, it can be used in gazebos and on piers, on balconies, etc. Fences and stairs are made from the same polymer board. In general, good material.

What is a terrace board

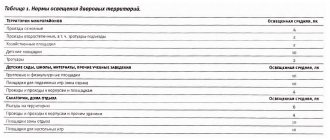

The decking board is intended for use outdoors, in light buildings. Most often they make flooring on a covered or open terrace; they are also used as flooring around pools, in gazebos, etc. The operating conditions are difficult, so increased demands are placed on the material for its manufacture. It must withstand all weather conditions well, absorb moisture poorly, and be resistant to ultraviolet radiation and biological damage. And also strong, durable, beautiful and inexpensive. That's another set of properties. There are not many materials that correspond at least partially.

Terrace board - molding for outdoor flooring

The same type of material is called decking from the English deсking, which translates as flooring, but more often as deck flooring. Apparently this is why you can also find the name “deck board”. Actually, it differs in that longitudinal grooves are formed on the front surface for water drainage. This is very necessary on decks. The same grooves make the flooring less slippery when it rains. Often (but not always) decking boards are also made with longitudinal grooves.

What are they made from?

Initially, very dense wood species with a large amount of resins were used for decking boards. Such breeds do not grow in our latitudes, and it is too expensive to buy exotic ones outside. Of the local wood, larch feels more or less at home outdoors, but it turns gray no matter how you care for it.

At first, the decking board was made of wood

Later, heat-treated wood appeared. It is kept at a temperature of 140-160°C, as a result of which its density increases, it absorbs less water (several times less). When properly processed, it is not affected by fungi. But such a board does not cost much less than the “exotic”. Still, this is wood, so maintaining the appearance is annual.

WPC board - what it is and what it is made of: a mixture of wood flour and polymer with a small percentage of stabilizing additives

Wood-polymer composite or WPC has appeared relatively recently. It is a mixture of wood fibers and polymer, to which coloring pigments have been added. Boards are formed from the resulting mass by extrusion. The coating cannot be called natural, since polymers are used. But it meets most of the requirements. Let’s say right away that high-quality WPC decking cannot be called cheap.

What and how are they made from?

Wood-polymer composite (WPC) contains wood flour (or agricultural waste to reduce the cost of products), thermoplastic polymer and various modifiers (giving the finished product special properties). The percentage of the first two components depends on the manufacturer and class of material.

The cheapest option contains 30% polymer and 70% wood flour, which makes the material hydrophilic, less wear-resistant and more fragile. With an equal ratio (50/50), it is possible to obtain a material with optimal properties.

The content of 60% polymer and 40% flour affects the aesthetic qualities of the coating (externally, the decking looks not like a board, but like plastic), but at the same time it gives additional strength and resistance to environmental factors. The inclusion of chemical additives (modifiers) in the composition does not affect the environmental friendliness of the material, since their amount does not exceed 5%.

The manufacturing process is based on extrusion - a method of producing a product from a polymer by pressing it in molten form through the molding hole of a processing machine - an extruder. Less commonly used are injection molding and compression molding.

Polymer board for terraces: pros and cons

Wood is, of course, beautiful. But outdoors it requires regular care. Even with the condition of using modern chemistry. The same wood oil looks great throughout the year. But after a year the coating must be renewed. Considering that the cost of good oil for difficult operating conditions is quite considerable, this is quite a significant expense. Well, you also need to take into account the time it takes to process. Even if the oil just needs to be applied to the wood, it also takes time.

This is a photo a year after installation.

At the same time, wood swells from moisture and shrinks in the sun. And these are constant problems with the “humpiness” of the flooring. In general, those who have had the good fortune to maintain a wooden deck want to try something different. WPC decking boards are often considered as an alternative. Firstly, it does not require special measures to maintain its appearance. Just needs cleaning. Secondly, it is cut/drilled with a conventional tool. A saw can be for wood or metal, but a drill is better for metal. There are other advantages.

pros

You may like the appearance of the polymer board or not. And for the street, the coating is at least not bad and, with the right choice, looks decent even after years. Here are the advantages of WPC decking:

- Durability. The declared service life is 10-25 years. But these are only factories that provide accompanying documents and do not hide their name. Unnamed products are a risk, as they can fall apart within a year.

- Tolerates difficult operating conditions well. Operating temperature range -50°C to +50°C.

- Does not require maintenance. You just need to sweep away the dirt and wash it occasionally. The recommendations include annual intensive cleaning. There are no other wishes. But we need to take into account the color. If you choose a light decking, it is clear that marks and dirt will be visible on it. You either have to fight this or come to terms with it. Or take “non-staining” colors.

The joints will be visible and you will have to come to terms with it... Or somehow play with it by making a drawing - Doesn't change appearance. It just fades a little. The intensity of fading depends on the amount of wood in the composition. It can be from 50% to 80%. The more wood fibers, the more natural the look, but it also fades more intensely.

- Almost does not absorb water and, as a result, does not swell. Absorbs about 1-2% depending on the composition.

- Doesn't change geometry.

- Does not rot, is not affected by fungi.

- Some types allow you to restore the appearance (corduroy). The polymer board with “stripes” is processed at the exit either with a metal brush or emery. And the appearance is also restored - with a brush or sandpaper.

In general, the list of advantages is quite decent. A WPC terrace looks good, even after several years of use. There are different textures and surfaces, different colors.

Minuses

There are no construction and finishing materials without shortcomings. The first disadvantage of WPC decking is the high temperature expansion. And this entails difficulties with installation. There are types of WPC, when using which you can ignore the increase and decrease in size. But not with everyone. Usually, special fastening is required - on mounting plates-clamps or on special fasteners.

The second disadvantage is that wood-polymer concentrate does not like to be in water. You can get it wet, but you shouldn’t keep it in a puddle. Therefore, you need to make sure that the water rolls off as quickly as possible. In the case of a non-continuous flooring (with a gap between the boards), the water drains away quickly in any case. But when laying continuously, it is better to choose the direction of the “grooves” so that the water drains as quickly as possible. You can arrange a slight slope towards the edge of the site.

As you can see, there is a difference in colors. Some manufacturers do not consider this a defect

What else is worth remembering. WPC consists of 50-70% wood. The resulting strength is not as high as tile or stone. You should not hit it with a hammer or drop large and heavy objects. It will either crack or dent, or the top wall of hollow boards may break. So this also needs to be kept in mind.

Of the operational problems, perhaps, that's it. There are still problems of choice. The fact is that we do not have a standard for WPC and they make it from whatever they have. But there are certain signs by which you can cut off obviously low-quality products. However, there is such a problem.

One of the unpleasant aspects of installation is that when cutting, the teeth of the saw quickly wear out, so you need more than one blade and, preferably, of good quality.

Production

To obtain a high-quality product from WPC, it is necessary to strictly adhere to the technology, as well as the proportions of all components of the composite.

It should be noted that this can only be achieved by fully automating the production of this material.

In this case, the following procedure is observed:

- The polymer and wood filler are crushed using first shredders and then mills. This makes it possible to use not only primary, but also secondary polymer collected at landfills or at recycling collection points.

- They reduce the moisture level of crushed wood raw materials, because water boils when the temperature rises, forming bubbles that mix with the molten polymer, reducing the strength of the product after hardening. This operation is carried out using vacuum units, because the lower the pressure, the higher the boiling point, therefore, with strong vacuum, the liquid turns into steam at room temperature.

- Mix both components in the required proportions and add substances to them that improve the properties of the finished product. To do this, all components are fed into one or two screw installations, which operate like a meat grinder screw.

- is melted in special installations using electric or oil heaters for heating.

- The molten mass is fed into a screw conveyor , which not only delivers the finished mass to the die and creates pressure sufficient for molding the part, but additionally mixes the melt.

- Using a die (a specially shaped hole that inversely follows the contours of the future part), a finished part is formed .

- is cooled in a water bath, then the desired pattern is applied to the surface using various machines.

- Cut with circular saws into pieces of the required length.

At each stage, it is important to complete the work not only with high quality, but also within a certain time , so that there is no downtime of the line due to a lack of material or the inability to process its excess.

To ensure the required dosage of the remaining components, depending on the technology, they are either loaded into the mixer in batches of the required volume/weight, or fed through calibrated holes.

Some companies not only produce products from WPC, but also sell pellets from the melted and hardened mixture, which are used as a material on those lines where there are no wood and polymer shredders.

In addition, this approach allows you to create a reserve of granules in case of breakage of grinders or quickly launch several extrusion lines. You will find more detailed information about the equipment and technologies for the production of WPC products in the article WPC Production.

WPC composite board: which polymer is better

As already mentioned, polymer decking is a mixture of split wood and polymer. But polymers are a whole class of materials. WPC is made with PVC (polyvinyl chloride), polyethylene (PE) and propylene (PP). The ratio of polymer and wood is different. There are species that are 80% wood, and others that are 50/50. The appearance depends on the amount of wood in the composite. The more it is, the more “wooden” the WPC looks. But such a polymer board fades more, and it is softer and wears out faster.

WPC properties depend on the polymer

The type of polymer also affects the appearance. WPC based on propylene has the most “natural” look, while PVC has the most “plastic” look. But each type of composite has its own nuances, and we’ll talk about them below.

Another thing is oil tolerance. For propylene and polyethylene, oil is a solvent. If oil is spilled on a coating based on these materials, it must be cleaned up as soon as possible. For this you can use water with a special detergent for polymer decking or dish soap. Then the surface must be thoroughly cleaned by rinsing several times with clean water. Oils are not dangerous for PVC. This is the advantage of this type of WPC boards.

Flammability

All wood-polymer composite boards are combustible materials, but have varying degrees of flammability. A composite with polyethylene and propylene burns no worse than wood; it should not be used in fire hazardous areas. PVC burns worse, but releases chlorine in the process.

Choose the material consciously: properties of WPC based on different polymers

There are also concerns that polymer-wood boards have an unpleasant odor. In general, at normal temperatures it smells like wood. Only if the PVC-based composite is heated to +50°C does a characteristic odor appear. Therefore, this material is recommended for installation under a canopy, and not in the open sun.

Thermal expansion and ways to combat it

Any WPC decking board has a large thermal expansion - 3 mm per meter of surface. The figure is impressive, but this figure was measured when the temperature changed from -50°C to +50°C. Agree, in real conditions such a difference does not happen in one day.

However, thermal expansion is really high. With a board length of 6 meters, the increase in size will be about 8-10 mm, which is quite a lot. So a natural continuation of the topic is the problem of fasteners. How to attach WPC decking to avoid problems with thermal expansion? Depends on the type of polymer:

- Polymer terrace boards with polyethylene can be fastened through with nails or self-tapping screws. Polyethylene is a viscous and plastic material. It compensates for such movements due to viscosity. And there will be no destruction of either the board, joists or other support. Let us warn you right away, it is softer and washes out faster. But it wears off with intensive use. That is, in public places. There will be no such load near the house, which will significantly affect the appearance.

As one of the options for solving the problem of joints and thermal expansion - The composite with PVC and polypropylene is hard and brittle. This is good, since it wears out less, but it must be attached only and exclusively to the plates. And plastic ones won't work. They need to be made of stainless steel, and their cost is considerable. And this is an additional expense and a more complex and time-consuming installation. This type of composite decking board is good for public places. Where the most important thing is not the complexity of installation, but abrasion.

There is also a unique way to combat thermal expansion. The flooring is assembled from short lengths. There is no need to fit them closely, as they even recommend leaving gaps for efficient drainage of water. These gaps will compensate for the increase or decrease in size. It turns out to be a kind of parquet. There is even a coating with the same name - garden parquet. It is made from polymer boards. But its cost is much higher than that of a self-assembled one. Here you can play with colors and textures and get a very interesting covering for the terrace.

Sale of wood-polymer composite on favorable terms

EcoDecking sells WPC decking boards in Moscow, Sochi, Krasnodar (from its warehouses) and in all other cities of Russia from the warehouses of partners or dealers. If there is no warehouse in your city, we are ready to deliver on favorable terms. It is important that we do not make money on delivery, it is a free service.

Our company often runs promotions that allow you to buy composite boards on favorable terms, especially if you are a wholesaler or dealer.

Favorable conditions in our understanding are:

- Lack of minimum shipment quantities and loading transport requirements.

Often complicates re-ordering material - Reasonable price for components

Often sellers reduce the price of decking boards by increasing the price of components. In the end, it seems that the board was bought cheaply, but when you see the complete installation kit, the amount doubles or even triples. We are not trying to impose either the board or the components, but our price is more reasonable, so it is always rational to compare not only the cost of the decking board, but also the cost of the estimate as a whole. - Price for quality

We believe that the price for our product is much lower than its quality. We do not skimp on wall thickness and formulation - Availability

Our warehouses always have goods that will satisfy your need in a short time. - Production to order

By producing goods in size with a multiple of 10 mm, you can additionally save up to 15% of the cost of the decking board on site.

Types of WPC decking boards

We will not talk about materials, but about profiles and other technical issues. Let’s say right away that there are solid and hollow polymer terrace boards. Solid - a solid composite without voids. This type of flooring is good in areas with high traffic. These are public places such as summer areas of cafes, embankments, piers, etc. Hollow - suitable for private property. Terrace near a private house, decking around a swimming pool, pond.

Solid - a solid composite, cellular can have different profiles. Far right - most common

By flooring method

Next, there are two types of boards - solid flooring and with gaps. Solid flooring has tongue and groove like a tongue and groove board. Installs with virtually no gaps. The coating still allows moisture to pass through, but it leaves slowly and there may be puddles on the surface in heavy rain. The advantage of such flooring is that small objects do not fall through the cracks. The second positive point is that it is easier for ladies to walk in heels.

The edge of the plate clings to these grooves. This way the decking is attached to the joists

The polymer board of the non-continuous flooring is laid with some gap - a few millimeters. With this installation, moisture does not form puddles, but seeps under the flooring. Well, the problem with longitudinal thermal expansion is solved. True, walking in thin heels on such flooring is not very comfortable. It's good that today they - thin heels - are not in fashion.

WPC decking board: profile

A non-solid wood-polymer board is also called cellular. It can be a closed profile or an open one. Closed is when there are two horizontal surfaces with bridges between them. When choosing, you need to pay attention to the thickness of the partitions and horizontal planes.

Compare regular (right) and enhanced (left). They are given on the same scale

For increased loads on the terrace there is a reinforced type of decking. Thicker webs and horizontal surfaces increase flexural strength. This means that when laying on joists, they can be installed less frequently.

WPC decking board with open W-shaped profile

An open or W-shaped profile of a composite board for terraces is when there is only one horizontal surface - on top, and below only the ends of the ribs. This type, of course, is cheaper and has a smaller height, but it is better to use it in places where the load is very light. Although, there are types with thick bridges as in the photo on the right. Quite a worthy option for laying not on logs, but on a flat concrete platform. But don’t think that it will cost much less. The difference in price is small - about 10-15%, since the consumption of the composite is increased due to the thickness of the partitions.

By type of surface

Polymer decking can have different surfaces. In general, there are two types of surface:

- With grooves. This type is called "corduroy". There are larger and smaller sizes. The width of the strips is from 2-3 mm to 5-7 mm. Accordingly, they call it microcorduroy or simply corduroy, there is also a large one... This board does not slip and wears off slightly. The downside is that it’s not very convenient for cleaning; you have to sweep debris out of the grooves. The best cleaning agent is Karcher.

A composite decking board with a corduroy surface (with grooves) is better in operation. - Wood imitation. No matter how beautiful it looks, no matter what protective layers it is covered with, it is more slippery and wears off faster. And it also costs more. But cleaning is easier. An ordinary broom is quite enough. In general, this is an excellent option for flooring where people walk barefoot or wear slippers. For example, a porch in the backyard. It is better not to use such flooring for covering in front of the main entrance - it will quickly wear off.

The same “grooves” can be polished or brushed. Sanded is smoother; brushed with a metal brush has a certain degree of roughness. Both types of surface can be restored. The first type is with sandpaper, the second is with a metal brush. The color difference will not be noticeable, since the material is dyed in bulk. Wood imitation boards cannot be restored. The relief in especially loaded places will be erased and nothing can be done about it.

If there is no processing and the surface is “cast”, this is not a very good sign. Good manufacturers carry out pre-sale preparation, giving the product a “marketable” appearance. So it is better not to consider the material without processing. No matter how attractive the price is.

WPC board for fence - characteristics, properties and purpose

What is special about the DPK board?

- Types of material

- Fence installation steps

- How is the support mounted?

- Where else is WPC used?

- Characteristics

Nowadays, nothing is out of place, the same applies to the manufacturing technologies of building materials used for the construction of fences. Boards made of composite materials are in demand today. It is made using the extrusion method, i.e. The composite material is passed through special holes. The composition of the raw materials is 40% virgin polypropylene, 55% wood flour and 5% additives. WPC board for fence

Positive and negative qualities

The abbreviation WPC stands for wood-polymer composite; a building material is made from wood and a mixture of low-molecular substances that form a polymer. Due to polymerization, products are endowed with unique properties, which makes them better than those made of wood and ceramics.

Why does it make sense to use this type of board to build a fence? There are many reasons:

- there are no lead additives in the finished material, which means that it is environmentally friendly;

- a colorless gas with a pungent odor (also known as formaldehyde) is not released during operation;

- the likelihood of mold and mildew formation is reduced to a minimum, rotting processes are not supported.

Decking boards made of composite materials are characterized by resistance to changes in air temperature, high levels of humidity, and combustion processes. The installation process is simple, and in terms of design, wide possibilities are offered. Having built yourself a fence from it, you will not have to paint it every year.

There are some disadvantages too.

- As a result of rough mechanical impact, scratches may remain on the surface. But if you use a special pencil designed for wood restoration, everything can be corrected.

- Under conditions of critically high/low air temperatures or operation at high humidity for a long time, there is a possibility of deformation of the boards. For this reason, manufacturers recommend leaving a gap between the fence elements.

Types of wood-polymer fencing

The described material can be used in different ways. The classic version involves the construction of a fence from profile posts, between which boards are placed in a vertical position, with a wide step taken between them. WPC board for fence

You can also try to implement the Country style, this is when the profile supports are connected by transverse elements (top, bottom), the main parts are arranged crosswise, and the possibility of crossing several boards is also allowed. If you have heard about such a variety as a plastic picket fence, then know that this is when there are two supports with the same number of transverse logs, which imitates a traditional picket fence.

Are you planning to fence your front garden or decorate your gazebo in an original way? Then you can make sections - trellises. They are rectangular frames with a span, made of lattice. To prevent it from being visible on the street what is happening in the yard, you can give preference to a solid composite fence with a horizontal orientation. It is extremely simple to build; first, the supports are installed, and the boards are attached to them overlapping/close to each other. Depending on which option you prefer, you may end up with something similar to closed blinds or a continuous canvas. WPC board for fence

An interesting design option is wicker. This is when individual sections include a large number of narrow elements. They are located in a diagonal direction, thus it is possible to form a grid of small-sized rhombuses. Alternative design options exist, but they are rare in life.

Basic principles of installation

As you already understand, fences made from WPC decking boards are not uncommon; if you want to try to build one with your own hands, then you need to start by remembering what parts the fence system consists of. The following parts and assemblies are necessary for complete completion:

- support pillars;

- caps on them that perform a decorative and protective function;

- transverse profiles;

- boards;

- steel brackets required for supports.

The basis for the fence can be a strip foundation or metal pipes. In the first case, the concrete mixture is poured into a specially constructed structure in the ground. In the second case, pipes are placed in the ground, after which they are concreted or secured with anchors. Supports made of wood composite will be placed on the poles, and transverse profiles/railings will be attached to them. Products made from wood-polymer composites can be drilled and sawed. The maximum height of the fence can reach 18 cm. WPC board for fence

Options for installing support pillars

A board made of composite materials for a home is always attached to a support, the installation of which can be done in various ways, for example, to a pillar made of concrete or brick. For these purposes, the elements are cut to the required height, fixation is ensured by using dowel-nails, which is done strictly vertically. Alternatively, the support can be mounted into the ground up to a third of its length, either with or without a metal pipe. Before this, you should make a drainage pad.

Some experts install supports in the ground with a bracket. Its lower part is made pointed, and a composite pole is put on the top of the head that remains above the surface of the earth and fixed using special screws. If a hard surface, such as a concrete floor, will be used as the base for the fence, then the brackets are used of a different type. Their peculiarity is the presence of a platform at the bottom, designed for fixation on a flat surface. As you probably already understood, after the brackets are fixed to the floor, a support for the future fence is put on them. WPC board for fence

At the next stage of installation, horizontal profiles and, if necessary, railings are secured. During the installation of the picket fence, connections are made using special-purpose fastening bolts. To ensure that the holes made in the profiles are at the same level, it is recommended to use a building level. At the end of the fence construction process, the fences between the support posts are filled, the work is done using boards. They are mounted on profiles; this can be done vertically or horizontally, with gaps or tightly.

Reviews of WPC fencing boards indicate that the material is excellent for use for these purposes. The secret is its combination of the best properties of natural wood and synthetic polymers. This makes the products not only beautiful, but also strong and durable.

Scope of application of wood-polymer composites

Due to its unique characteristics, the material has gained immense popularity. This applies not only to the industrial sphere, but also to construction and everyday life. Such products are used to pave areas, paths in gardens, and open terraces. Not everyone knows, but it turns out that siding is even made from this material, which is used for finishing facades. In big cities, you can often find flower beds in park areas and alleys, decorated using composite products, the same applies to personal plots.

In addition to the fence, the board is used to construct patio bases, flooring, and the manufacture of building elements such as balustrades, picket fences, roofing, and openings (door/window). It has also found application in industry; containers and pallets are made from it. Production of frame parts of furniture, equipment of playgrounds for children

buildinfo.ru

Dimensions of WPC decking boards

Polymer decking is not standardized, so there is no need to talk about any uniform sizes.

Each manufacturer produces the products it considers necessary. We can talk about the spread of parameters and what sizes are optimal. An important parameter is the thickness of the WPC board. But not on its own, but in combination with the thickness of the partitions and the thickness of the front layer. This is what gives the product strength and is responsible for wear resistance and service life. So, here are the parameters of a hollow-core composite deck board:

- thickness from 19 mm to 32 mm;

- width from 13 cm to 26 cm.

The dimensions of WPC terrace boards are not standardized and can be any size.

See the partitions for yourself, information about them is almost not indicated anywhere. It is advisable that they are no thinner than 3-4 mm, ideally 4 mm. As for horizontal surfaces, it is better if they are 6-8 mm or more.

When choosing the dimensions of a wood-plastic decking, remember that the principle of laying it is the same as that of a regular board - on logs. These are bars of rectangular or square cross-section. The thinner the board, the more often you need to install logs. Otherwise, the coating will sag under your feet. And yes, a thicker board costs more, but requires less lag. There will definitely be a difference in cost. But it is usually not so impressive when you consider the cost of the lag too.

WPC stairs also look beautiful and are easy to use

So what size is it better to take a WPC decking board? For private use, take decking with a thickness of at least 24-26 mm. As for the width, it's a matter of taste. But the wider the board, the less fasteners you need. With the specified thickness of the boards, the installation step for the logs is 40-50 mm.

DNP and SNT - what is it and how does it stand for?

Russia is the largest state in the world, which has the largest lands. Therefore, it is not surprising that almost every resident of this country has their own suburban area. This type of property is subject to accounting and registration, but not everyone knows that each land plot belongs to a certain category. Today, the territories are used not only for residential developments, but also for other types of activities (for example, for agricultural work). This means that if a person plans to build a house on a plot, but at the same time acquires territory on which buildings cannot be built, then he is actually breaking the law.

Therefore, before purchasing a plot of land, it is very important to find out what type of zone the selected zone belongs to (SNT, DNP or individual housing construction). In addition, knowing the definitions of these concepts will help you choose the most optimal option. After all, just like any type of property, private territory is also classified.

In order to understand the types of land holdings, it is worth considering the meaning of these abbreviations:

- DNP (dacha non-profit partnership) is a suburban area on which the construction of buildings for residence is allowed.

- Individual housing construction (individual housing construction) is land for the construction of residential buildings with subsequent registration.

- SNT - a plot intended for gardening or for organizing country farming (horticultural non-profit partnership).

Individual housing construction is the least popular today, since the cost of such land is too high. Although the process of registering this type of property is considered quite simple. However, it is much more profitable to purchase or build a house in SNT or DNP. Lands of these categories can only be a component of agricultural areas.

However, it is worth considering one nuance. According to recent changes in legislation, in some cases the DNP may be located on the territory of the settlement. Individual housing construction may even be present exclusively on lands intended only for residential construction for the purpose of year-round living.

Agricultural land

Having understood the definition of DNP and SNT, what they are and how these categories differ from each other, it is worth considering in more detail the territories intended for farming. Lands of this type are most common in Russia and occupy 1/4 of the entire area of the Russian Federation. In terms of scale, they are second only to forests.

Agricultural land does not mean just one class of land. These can be hayfields, vineyards and much more. For example, today you can find SNT - gardens, without any residential buildings.

Some believe that this type of land can be located extremely far beyond the boundaries of cities and towns. However, it is not. It is worth considering that SNT is a type of land that can also be located in the immediate vicinity or on the territory of a populated area.

In addition, agricultural areas also include crop and livestock farming, which in turn are divided based on the specific type of activity.

Differences between DNP and SNT

These types of land plots are of increased interest to citizens who want to spend the summer months at their dacha, living in their home and growing vegetables on the plot. Land areas of the DNP and SNT types, reviews of which are mostly positive, predominate in Russia. If we talk about the convenience of paying fees, then almost everyone is satisfied with these farming systems.

If we talk about the similarities of these categories of land, then it is worth saying that DNP and SNT belong to non-profit partnerships. However, there are some differences.

For example, not everyone knows that SNT is a type of land that appeared in Soviet times. By and large, such lands are small gardens where people of different incomes can live, who may not even know each other. At the same time, there are usually no communications on the territory of the sites. That is, according to the “every man for himself” principle.

DNPs are larger settlements where people most often live throughout the year. As a rule, such areas have centralized sewerage and other amenities. Cottage villages can be included in this category. In this case, the life of plot owners is more organized.

Price

If we talk about the cost of SNT and DNP, then there is also one nuance to consider. You need to decide whether we are talking about purchasing a membership (which means paying for the plot itself, the house and existing communications) or whether the future gardener wants to know how much he will have to pay for the use of the land during the entire period of his stay on the plot.

If we talk about the initial purchase, then it is worth considering that SNT is a cheaper type of property. DNP in this case will cost much more. The same applies to subsequent residence on earth. The fact is that DNP implies the use of more modern communications and much more. In an ordinary SNT summer cottage, everything is usually limited to a well and a separate bathroom, which, of course, will be much cheaper.

The hidden cost of SNT and DNP

It is worth saying a few words about additional costs that may become an unpleasant surprise for the owner of a new suburban area. Of course, after purchasing land, every person wants to create the most comfortable conditions for themselves. The plots rarely have communications, so you will have to pay for the installation of a gas pipeline, electricity and sewerage. You also need to invest in road repairs and arrangement of access roads. In addition, many people prefer to install cable television into their home and provide themselves with a telephone line.

Based on this, DNP will have a higher hidden cost, since SNT rarely pays attention to such amenities.

Features of SNT

This type of property has some restrictions that should be taken into account before purchasing land. The fact is that in this case the entire team of the partnership bears financial responsibility. This means that if one of the owners decides to file a complaint with the court (for example, about the condition of the roads), it will not be considered. All decisions on controversial issues are made exclusively at general meetings.

The opposite situation occurs if one of the property owners in SNT does not pay mandatory contributions. In this case, his debt is divided among all members of the partnership, who will be forced to repay it.

In order to obtain registration in a SNT country house, it is necessary to confirm the absence of other housing, as well as create all the necessary conditions for permanent residence.

Based on this, it is obvious that in the case of gardening partnerships everything depends on the honesty and integrity of the management.

Features of DNP

It’s worth saying right away that it is impossible to obtain registration in this case. The same applies to the ability to grow vegetables and fruits on the plot. Of course, no one forbids doing this, but it is worth considering that DNPs are usually located on less fertile lands. Cottage owners rarely engage in agriculture.

In addition, the activities of the DNP are largely aimed at creating comfortable conditions for permanent residence, and not at arranging vegetable gardens or orchards.

Which is better: SNT or DNP?

In this matter, everything depends on the financial security and wishes of the future owner of the suburban area and real estate. If a person plans to spend only 3 months a year in nature, then there is no point in investing in DNP. SNT is quite enough to start growing vegetables and arranging a small garden. In addition, in the summer there is no need for heating or hot water, so you can save a lot on these amenities. Also, taxes on SNT are much lower, which again allows you to save an extra penny.

Once you settle into a DNP, you need to prepare for big expenses. A higher standard of living will have to be paid accordingly. You will also have to do the organization of your daily life yourself. On the other hand, obtaining registration in the DNP is much easier. This is due to the fact that the house in this case will most likely immediately be suitable for permanent residence. You will have to invest huge sums of money in SNT to furnish housing, but even under this condition you can get a refusal.

A few words about individual housing construction

Don't forget about the existence of another type of plot. If a person wants to obtain registration in the simplest way, then individual housing construction is the best option. A nice bonus will be that local registration will allow you to find a job close to home and send your child to study at a nearby school.

In addition, lands of this type are characterized by a developed social infrastructure. This means that shops, markets, entertainment centers, police stations, kindergartens, hospitals, etc. are necessarily located near the house.

Another advantage of this type of property is that the property can be mortgaged to obtain a loan.

However, the cost of individual housing construction is quite high. By and large, this type of property is least of all classified as suburban. If we are talking about buying a dacha, then the choice is between SNT and DNP.

In custody

The article examined the main types of suburban real estate ownership. SNT and DNP have their own disadvantages and advantages. To make a choice in favor of one type of plot or another, you should first take into account your wishes, financial capabilities and the need to obtain registration. Guided by the recommendations described above, everyone will be able to purchase exactly the type of property that suits them best.

Installation methods

WPC decking boards can be laid on joists or on a concrete base. But only certain types of coating are placed on concrete and the site must be almost perfectly level. Most of the polymer deck boards are placed on the joists. Lags can be:

- Wooden antiseptic, impregnated with a composition for direct contact with the ground.

- Special ones made of the same material are logs made of WPC.

- From a profile pipe.

WPC decking board: installation system

Logs for laying decking boards can be laid on a prepared concrete platform. Concrete can be in the form of slabs or screed. Possible installation on piles with strapping or posts. If the base is uneven, the logs are leveled using spacers. It is better to use rubber ones, but you can cut glass insulation or other material into squares that has sufficient strength and waterproofing properties.

This is roughly how a composite deck board is attached. In general, the form of fasteners and the distance between the boards are different for each company.

Usually special logs made of WPC are recommended. They have a special groove for installing fasteners - metal Z-shaped plates. Such a system must be offered by the seller. It is problematic to use fasteners from other companies - size mismatch is almost guaranteed.

A frame has been assembled for laying WPC decking boards from a profile pipe

Logs made of wood or profile pipes can be fastened through, but the cap should not stick out. As an option, there is a perforated tape that is attached to the sides.

WPC terrace board: decorating the edges of the flooring

After laying and fixing the decking board, you need to close the sides of the platform where the logs are. For this, there are overlays in the form of strips of a certain width and a corner made of WPC. The composite corner cannot be thin. Its thickness is several millimeters. In places where there is active walking, it wears off quickly. Therefore, for these areas they often offer an aluminum corner painted to match the coating. This is not the only edge finishing option. There are also edge plugs from the same WPC, but they do not cover the joists. If you don't care about this, use only stubs.

If the platform or terrace is adjacent to the house, you can trim the joint with WPC plinth. But the option with a plastic baseboard is no worse. They come in a variety of shapes and colors and are much cheaper. If you need to save money, this is one of the ways.

Economics of choice: WPC or wood (larch, pine) for the terrace

The benefits of WPC material are clearly demonstrated in our comparative article, which objectively examines larch and WPC products. Article wood or WPC

In a nutshell, over a 5-year period of ownership, high-quality WPC becomes many times more profitable than larch decking boards.

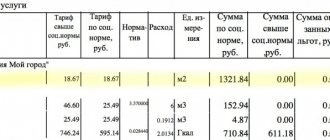

As can be seen from the table and photo, the use of WPC in the next 5 years is much more profitable than the use of natural wood. Tests using a simple boiling method also confirm the greater stability of WPC relative to larch.

How to choose quality WPC decking

If you are offered an imported WPC decking board at a price below the market average, it is better not to take it. Usually these are products made either in China, or (even worse) in a garage on old equipment from who knows what. There are very good Chinese boards made of polymer-wood composite, but there are many more low-grade products. It’s easier to buy from companies with a proven reputation.

The desire to save money is understandable, but cheap fish...

When choosing composite decking, here's what to look for:

- The structure should be uniform with inclusions of wood fibers. There should not be areas with different surfaces.

- The lintels are of the same thickness, the edges are clear and even.

- The surface is free of cavities, castings and other defects.

- Look at the sides, front and bottom edges. There should be no pronounced waviness.

- Chamfers and grooves are at the same distance, the same depth.

- There should be no delaminations, crumbs, etc. on the cut.

- If you try to break off a small piece at the cut site, the WPC material should not even bend, let alone break and crumble.

If you have the opportunity, look at all the colors offered by the manufacturer. Normal companies should have light shades. This means that the wood used is normal. If the colors are only dark, bark and other waste are used instead of normal wood. But this is not the same material at all and no one guarantees its properties.

WPC manufacturers

The material is produced by many domestic and foreign companies. The list is extensive.

- Ligna Tek is a well-known Russian company. The first one launched the production of decking in Russia. It produces decking boards in several colors and sizes.

- POLYWOOD – produces terrace finishing using its own patented technology. The boards are available in 3 shades.

- DORTMAX – offers products in the middle price segment.

- WERZALIT – produces hollow and solid boards.

- DeckMayer is a German company that offers not only terraces, but also facade boards for building finishing.

WPC decking board: manufacturers

Oddly enough, not many company names are heard. Only a few work on the company's image. And since there is no standard, it is dangerous to take an unnamed product for which there are no documents or guarantees. Who should I complain to if problems arise?

A little more horror

In general, here are the manufacturers that are constantly on everyone’s lips:

- Waldeck.

- Woodgrand (Russia).

- Werzalit is a German company, the quality is excellent, but the prices are high.

- Savewood is a Russian company, quite decent quality.

- TERRADEK (Terradek).

- Polywood.

- MasterDeck.

- Darvolex.

When choosing a manufacturer, look for those that have websites. Today, new materials are promoted more effectively through such resources. And if a company invests in this, it is interested in ensuring that its products are of decent quality. Otherwise, a hail of negativity is guaranteed.

Online store of composite products from WPC

The official website of Ecodeking is a verified online store selling WPC composite boards. We deliver goods throughout the Russian Federation and the CIS. If photos on the Internet are not enough to make a positive decision about purchasing, then you can order samples of the main products, or get acquainted with the products from our dealers, who have representative offices in almost every major city in Russia. They provide a full range of additional services, which usually include: measurement, estimate calculation, visualization, material delivery, installation and supervision.

Application options for WPC

Wood-polymer composites are used to make deck boards, floor boards, profiles for roofing and interior wall decoration, and facade boards that replace and surpass conventional siding.

WPC boards are successfully used in the construction of street cafes, private saunas, gazebos, and in the design of a country house and garden plot. In urban areas they are used for finishing balconies and loggias. Let's consider the main areas of application.

Terrace and patio area Garden paths Cladding balconies and loggias Fishing bridges and piers Area around the pool Facade of a private house and buildings Arrangement of flower beds and beds Fences and decorative fences

DPK - from Russian

Translation: from Russian

See also in other dictionaries:

- DPK - Democratic Party of Kosovo Kosovo, political. DPK wood processing plant organization Source: Example of use of JSC DPK "Severny", Krasnoyarsk DPK D ... Dictionary of abbreviations and abbreviations

- DPK- - wood stove heater in marking Source: Example of using DPK 16 ... Dictionary of abbreviations and abbreviations

- DPC - Human duodenum Democratic Party of Kosovo Democratic Party of Kurdistan Wood plastic composite (English)Russian. Magazine "Home PC" Country consumer cooperative ... Wikipedia

- DPK - long-range cavalry support Democratic Party of the Convention (Liberia) Democratic Party of Kurdistan divisional party committee division of border ships ... Dictionary of Russian language abbreviations

- DPK "AK ZHOL" - DPK DPK "AK ZHOL" Democratic Party of Kazakhstan Kazakhstan, political ... Dictionary of abbreviations and abbreviations

- The Kurdistan Democratic Party (KDP) was created in 1946. It led the struggle of the Iraqi Kurds for their national rights. She actively participated in the national liberation struggle of the peoples of Iraq against colonial rule. After the July Revolution of 1958 in Iraq, it was included in... ... Great Soviet Encyclopedia

- DPKV - DPK DPKV crankshaft position sensor injection engines DPK engine ... Dictionary of abbreviations and abbreviations

- Democratic Party of China - Check neutrality. There should be details on the talk page... Wikipedia

- Kurdistan Democratic Party - This term has other meanings, see Democratic Party. Kurdistan Democratic Party Leader... Wikipedia

- Iraqi Kurdistan - Kurdish Kurdistan. حكومه تى هه ريمى كوردستان, Ḧikumetî Herêmî Kurdistan ... Wikipedia

- Kurdistan Democratic Party - Leader: Masoud Barzani Date of foundation: August 16, 1946 Headquarters: Erbil (in the 1990s) ... Wikipedia